and Value-added Technology

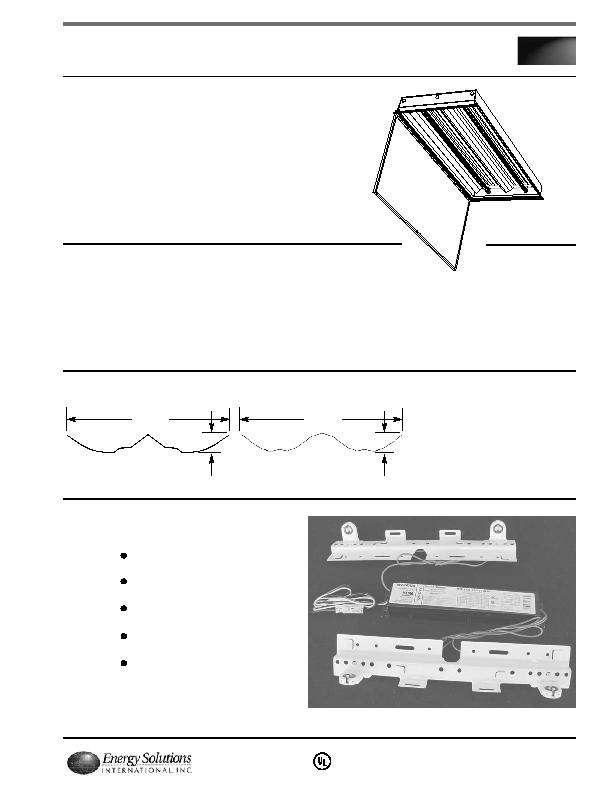

steel. Prepunched for lampholders and wire

passageway. Tabs on socket bars securely

mount the reflector in the correct position

relative to the lamps. Note: ESI's optional

uni-bracket is pictured in the diagrams.

85% reflective anodized finish, a 95% reflective

enhanced or film finish, or a 92% reflective white

enamel. The substrate is 0.020" high quality alu-

minum. The reflector profile is optimized using

computer analysis and manufactured using state

of the art CNC equipment. A protective premask

is applied to all reflective surfaces prior to manu-

facture.

bars are removed. With the new ballast and accessories

installed, the ESI socket bars are centered at the ends

of the fixture and fastened with two self-tapping screws.

The reflector is positioned between the socket bars. By

applying slight compression to the reflector peak, the

tabs on the socket bar are aligned with the punchouts in

the reflector. When the compression is released, the

tabs securely hold the reflector in place.

Disconnects and Accessories

Configurations