- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

www.bito.com

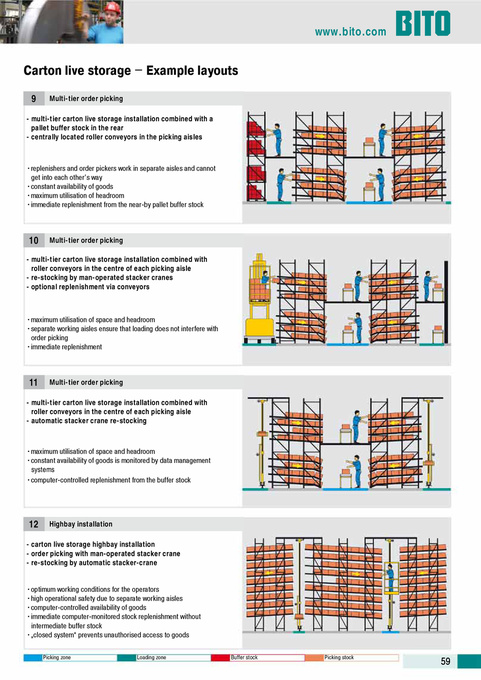

Carton live storage − Example layouts

9

Multi-tier order picking

- multi-tier carton live storage installation combined with a pallet buffer stock in the rear - centrally located roller conveyors in the picking aisles

•replenishers and order pickers work in separate aisles and cannot get into each other’s way •constant availability of goods •maximum utilisation of headroom •immediate replenishment from the near-by pallet buffer stock

10

Multi-tier order picking

- multi-tier carton live storage installation combined with roller conveyors in the centre of each picking aisle - re-stocking by man-operated stacker cranes - optional replenishment via conveyors

•maximum utilisation of space and headroom •separate working aisles ensure that loading does not interfere with order picking •immediate replenishment

11

Multi-tier order picking

- multi-tier carton live storage installation combined with roller conveyors in the centre of each picking aisle - automatic stacker crane re-stocking

•maximum utilisation of space and headroom •constant availability of goods is monitored by data management systems •computer-controlled replenishment from the buffer stock

12

Highbay installation

- carton live storage highbay installation - order picking with man-operated stacker crane - re-stocking by automatic stacker-crane •optimum working conditions for the operators •high operational safety due to separate working aisles •computer-controlled availability of goods •immediate computer-monitored stock replenishment without intermediate buffer stock •„closed system“ prevents unauthorised access to goods

Picking zone Loading zone Buffer stock Picking stock

59