- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

www.bito.com

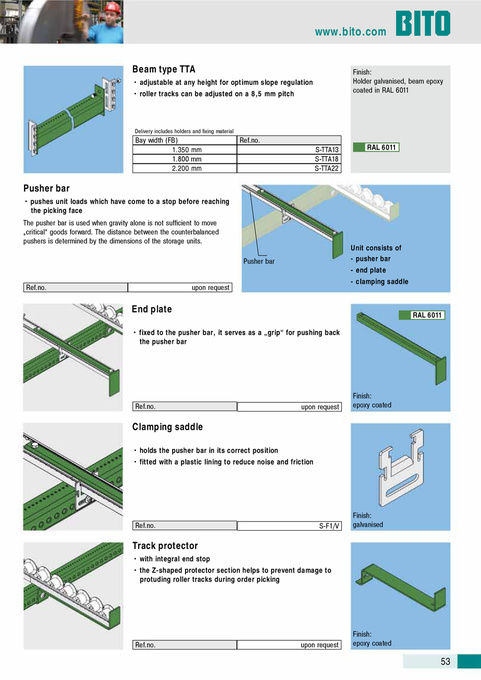

Beam type TTA

• adjustable at any height for optimum slope regulation • roller tracks can be adjusted on a 8,5 mm pitch Finish: Holder galvanised, beam epoxy coated in RAL 6011

Delivery includes holders and fixing material

Bay width (FB) 1.350 mm 1.800 mm 2.200 mm

Ref.no. S-TTA13 S-TTA18 S-TTA22

RAL 6011

Pusher bar

• pushes unit loads which have come to a stop before reaching the picking face The pusher bar is used when gravity alone is not sufficient to move „critical“ goods forward. The distance between the counterbalanced pushers is determined by the dimensions of the storage units. Pusher bar Ref.no. upon request

Unit consists of - pusher bar - end plate - clamping saddle

End plate

• fixed to the pusher bar, it serves as a „grip“ for pushing back the pusher bar

RAL 6011

Ref.no.

upon request

Finish: epoxy coated

Clamping saddle

• holds the pusher bar in its correct position • fitted with a plastic lining to reduce noise and friction

Ref.no.

S-F1/V

Finish: galvanised

Track protector

• with integral end stop • the Z-shaped protector section helps to prevent damage to protuding roller tracks during order picking

Ref.no.

upon request

Finish: epoxy coated

53