- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

Innovative Storage Solutions

r Upon

eque

st

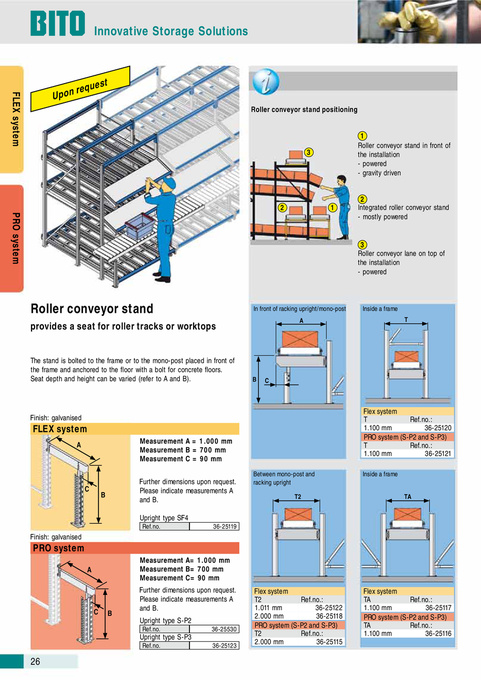

Roller conveyor stand positioning 1 Roller conveyor stand in front of the installation - powered - gravity driven 2 Integrated roller conveyor stand - mostly powered

FLEX system PRO system 26

3

2

1

3 Roller conveyor lane on top of the installation - powered

Roller conveyor stand

provides a seat for roller tracks or worktops

The stand is bolted to the frame or to the mono-post placed in front of the frame and anchored to the floor with a bolt for concrete floors. Seat depth and height can be varied (refer to A and B).

In front of racking upright/mono-post A

Inside a frame T

B

C

Finish: galvanised

FLEX system

A Measurement A = 1.000 mm Measurement B = 700 mm Measurement C = 90 mm Further dimensions upon request. Please indicate measurements A and B. Upright type SF4

Ref.no. 36-25119 Between mono-post and racking upright T2

Flex system T Ref.no.: 1.100 mm 36-25120 PRO system (S-P2 and S-P3) T Ref.no.: 1.100 mm 36-25121

Inside a frame TA

C

B

Finish: galvanised

PRO system

A Measurement A= 1.000 mm Measurement B= 700 mm Measurement C= 90 mm Further dimensions upon request. Please indicate measurements A and B. Upright type S-P2 Upright type S-P3

Ref.no. Ref.no. 36-25530 36-25123

C

B

Flex system T2 Ref.no.: 1.011 mm 36-25122 2.000 mm 36-25118 PRO system (S-P2 and S-P3) T2 Ref.no.: 2.000 mm 36-25115

Flex system TA Ref.no.: 1.100 mm 36-25117 PRO system (S-P2 and S-P3) TA Ref.no.: 1.100 mm 36-25116