- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

Innovative Storage Solutions

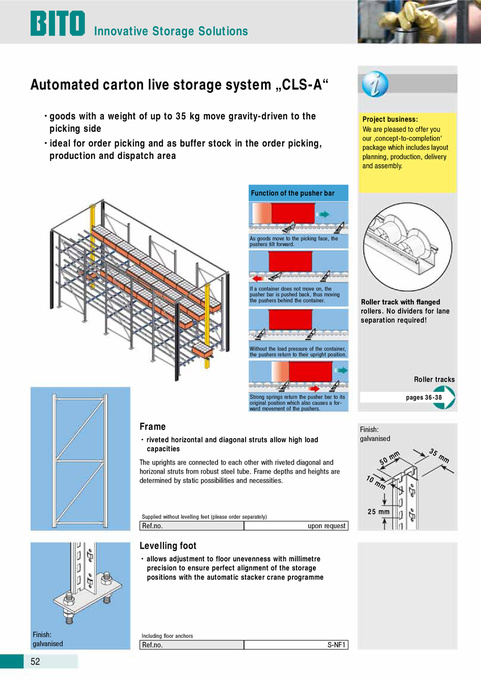

Automated carton live storage system „CLS-A“

• goods with a weight of up to 35 kg move gravity-driven to the picking side • ideal for order picking and as buffer stock in the order picking, production and dispatch area

Project business: We are pleased to offer you our ‚concept-to-completion‘ package which includes layout planning, production, delivery and assembly.

Function of the pusher bar

As goods move to the picking face, the pushers tilt forward.

If a container does not move on, the pusher bar is pushed back, thus moving the pushers behind the container.

Roller track with flanged rollers. No dividers for lane separation required!

Without the load pressure of the container, the pushers return to their upright position.

Roller tracks

Strong springs return the pusher bar to its original position which also causes a forward movement of the pushers.

pages 36-38

Frame

• riveted horizontal and diagonal struts allow high load capacities The uprights are connected to each other with riveted diagonal and horizonal struts from robust steel tube. Frame depths and heights are determined by static possibilities and necessities.

Finish: galvanised

m 50 10 m m m 35 mm

Supplied without levelling feet (please order separately)

25 mm upon request

Ref.no.

Levelling foot

• allows adjustment to floor unevenness with millimetre precision to ensure perfect alignment of the storage positions with the automatic stacker crane programme

Finish: galvanised

Including floor anchors

Ref.no.

S-NF1

52