- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Flash version

© UniFlip.com

www.bito.com

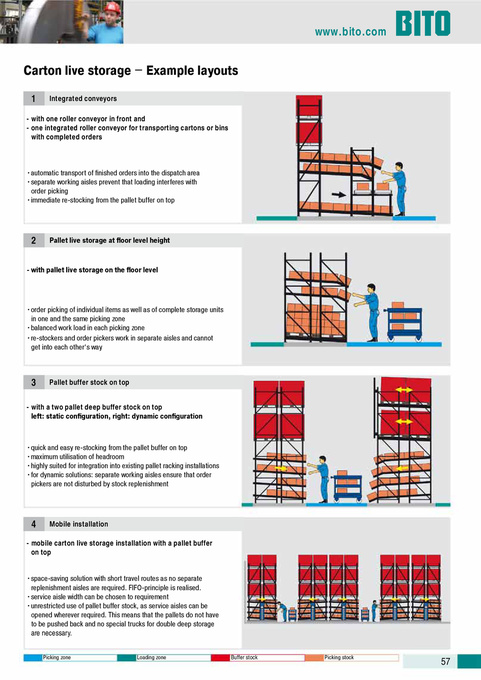

Carton live storage − Example layouts

1

Integrated conveyors

- with one roller conveyor in front and - one integrated roller conveyor for transporting cartons or bins with completed orders

•automatic transport of finished orders into the dispatch area •separate working aisles prevent that loading interferes with order picking •immediate re-stocking from the pallet buffer on top

2

Pallet live storage at floor level height

- with pallet live storage on the floor level

•order picking of individual items as well as of complete storage units in one and the same picking zone •balanced work load in each picking zone •re-stockers and order pickers work in separate aisles and cannot get into each other‘s way

3

Pallet buffer stock on top

- with a two pallet deep buffer stock on top left: static configuration, right: dynamic configuration

•quick and easy re-stocking from the pallet buffer on top •maximum utilisation of headroom •highly suited for integration into existing pallet racking installations •for dynamic solutions: separate working aisles ensure that order pickers are not disturbed by stock replenishment

4

Mobile installation

- mobile carton live storage installation with a pallet buffer on top •space-saving solution with short travel routes as no separate replenishment aisles are required. FIFO-principle is realised. •service aisle width can be chosen to requirement •unrestricted use of pallet buffer stock, as service aisles can be opened wherever required. This means that the pallets do not have to be pushed back and no special trucks for double deep storage are necessary.

Picking zone Loading zone Buffer stock Picking stock

57