- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Page 213

- Page 214

- Page 215

- Page 216

- Page 217

- Page 218

- Page 219

- Page 220

- Page 221

- Page 222

- Page 223

- Page 224

- Page 225

- Page 226

- Page 227

- Page 228

- Page 229

- Page 230

- Page 231

- Page 232

- Page 233

- Page 234

- Page 235

- Page 236

- Page 237

- Page 238

- Page 239

- Page 240

- Page 241

- Page 242

- Page 243

- Page 244

- Page 245

- Page 246

- Page 247

- Page 248

- Page 249

- Page 250

- Page 251

- Page 252

- Page 253

- Page 254

- Page 255

- Page 256

- Page 257

- Page 258

- Page 259

- Page 260

- Page 261

- Page 262

- Page 263

- Page 264

- Page 265

- Page 266

- Page 267

- Page 268

- Page 269

- Page 270

- Page 271

- Page 272

- Page 273

- Page 274

- Page 275

- Page 276

- Page 277

- Page 278

- Page 279

- Page 280

- Page 281

- Page 282

- Page 283

- Page 284

- Page 285

- Page 286

- Page 287

- Page 288

- Page 289

- Page 290

- Page 291

- Page 292

- Page 293

- Page 294

- Page 295

- Page 296

- Page 297

- Page 298

- Page 299

- Page 300

- Page 301

- Page 302

- Page 303

- Page 304

- Page 305

- Page 306

- Page 307

- Page 308

- Page 309

- Page 310

- Page 311

- Page 312

- Page 313

- Page 314

- Page 315

- Page 316

- Page 317

- Page 318

- Page 319

- Page 320

- Page 321

- Page 322

- Page 323

- Page 324

- Page 325

- Page 326

- Page 327

- Page 328

- Page 329

- Page 330

- Page 331

- Page 332

- Page 333

- Page 334

- Page 335

- Page 336

- Page 337

- Page 338

- Page 339

- Page 340

- Page 341

- Page 342

- Page 343

- Page 344

- Page 345

- Page 346

- Page 347

- Page 348

- Page 349

- Page 350

- Page 351

- Page 352

- Page 353

- Page 354

- Page 355

- Page 356

- Page 357

- Page 358

- Page 359

- Page 360

- Page 361

- Page 362

- Page 363

- Page 364

- Page 365

- Page 366

- Page 367

- Page 368

- Page 369

- Page 370

- Page 371

- Page 372

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Page 213

- Page 214

- Page 215

- Page 216

- Page 217

- Page 218

- Page 219

- Page 220

- Page 221

- Page 222

- Page 223

- Page 224

- Page 225

- Page 226

- Page 227

- Page 228

- Page 229

- Page 230

- Page 231

- Page 232

- Page 233

- Page 234

- Page 235

- Page 236

- Page 237

- Page 238

- Page 239

- Page 240

- Page 241

- Page 242

- Page 243

- Page 244

- Page 245

- Page 246

- Page 247

- Page 248

- Page 249

- Page 250

- Page 251

- Page 252

- Page 253

- Page 254

- Page 255

- Page 256

- Page 257

- Page 258

- Page 259

- Page 260

- Page 261

- Page 262

- Page 263

- Page 264

- Page 265

- Page 266

- Page 267

- Page 268

- Page 269

- Page 270

- Page 271

- Page 272

- Page 273

- Page 274

- Page 275

- Page 276

- Page 277

- Page 278

- Page 279

- Page 280

- Page 281

- Page 282

- Page 283

- Page 284

- Page 285

- Page 286

- Page 287

- Page 288

- Page 289

- Page 290

- Page 291

- Page 292

- Page 293

- Page 294

- Page 295

- Page 296

- Page 297

- Page 298

- Page 299

- Page 300

- Page 301

- Page 302

- Page 303

- Page 304

- Page 305

- Page 306

- Page 307

- Page 308

- Page 309

- Page 310

- Page 311

- Page 312

- Page 313

- Page 314

- Page 315

- Page 316

- Page 317

- Page 318

- Page 319

- Page 320

- Page 321

- Page 322

- Page 323

- Page 324

- Page 325

- Page 326

- Page 327

- Page 328

- Page 329

- Page 330

- Page 331

- Page 332

- Page 333

- Page 334

- Page 335

- Page 336

- Page 337

- Page 338

- Page 339

- Page 340

- Page 341

- Page 342

- Page 343

- Page 344

- Page 345

- Page 346

- Page 347

- Page 348

- Page 349

- Page 350

- Page 351

- Page 352

- Page 353

- Page 354

- Page 355

- Page 356

- Page 357

- Page 358

- Page 359

- Page 360

- Page 361

- Page 362

- Page 363

- Page 364

- Page 365

- Page 366

- Page 367

- Page 368

- Page 369

- Page 370

- Page 371

- Page 372

- Flash version

© UniFlip.com

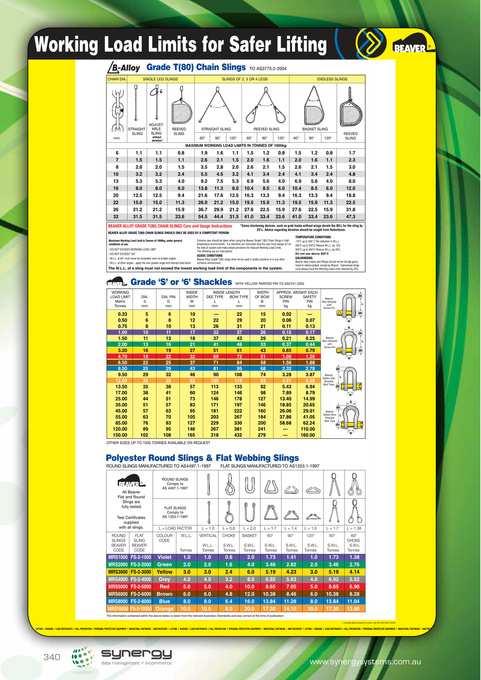

Working Load Limits for Safer Lifting

Grade T(80) Chain Slings

CHAIN DIA. SINGLE LEG SLINGS

TO AS3775.2-2004

ENDLESS SLINGS

SLINGS OF 2, 3 OR 4 LEGS

mm

ADJUSTABLE STRAIGHT ADJUSTSLING SLING ABLE without SLING

deration*

REEVED SLING

STRAIGHT SLING 60° 90° 120° 60°

REEVED SLING 90° 120° 60°

BASKET SLING 90° 120° REEVED SLING

MAXIMUM WORKING LOAD LIMITS IN TONNES OF 1000kg

6 7 8 10 13 16 20 22 26 32

1.1 1.5 2.0 3.2 5.3 8.0 12.5 15.0 21.2 31.5

1.1 1.5 2.0 3.2 5.3 8.0 12.5 15.0 21.2 31.5

0.8 1.1 1.5 2.4 4.0 6.0 9.4 11.3 15.9 23.6

1.9 2.6 3.5 5.5 9.2 13.8 21.6 26.0 36.7 54.5

1.6 2.1 2.8 4.5 7.5 11.3 17.6 21.2 29.9 44.4

1.1 1.5 2.0 3.2 5.3 8.0 12.5 15.0 21.2 31.5

1.5 2.0 2.6 4.1 6.9 10.4 16.3 19.5 27.6 41.0

1.2 1.6 2.1 3.4 5.6 8.5 13.3 15.9 22.5 33.4

0.8 1.1 1.5 2.4 4.0 6.0 9.4 11.3 15.9 23.6

1.5 2.0 2.6 4.1 6.9 10.4 16.3 19.5 27.6 41.0

1.2 1.6 2.1 3.4 5.6 8.5 13.3 15.9 22.5 33.4

0.8 1.1 1.5 2.4 4.0 6.0 9.4 11.3 15.9 23.6

1.7 2.3 3.0 4.8 8.0 12.0 18.8 22.5 31.8 47.3

BEAVER ALLOY GRADE T(80) CHAIN SLINGS Care and Usage Instructions

BEAVER ALLOY GRADE T(80) CHAIN SLINGS SHOULD ONLY BE USED BY A COMPETENT PERSON

Maximum Working Load Limit in Tonnes of 1000kg, under general conditions of use. • DO NOT EXCEED WORKING LOAD LIMIT • DO NOT EXCEED 120° • W.L.L. at 60° must never be exceeded, even at smaller angles. • W.L.L. at other angles - apply the next greater angle and relevant load factor.

*Some shortening devices, such as grab hooks without wings derate the WLL for the sling by 25%. Advice regarding deration should be sought from Robertsons. TEMPERATURE CONDITIONS

-10°C up to 200° C No reduction in W.L.L. 200°C up to 300°C Reduce W.L.L. by 10% 300°C up to 400°C Reduce W.L.L. by 25% Do not use above 400°C

Extreme care should be taken when using the Beaver Grade T(80) Chain Slings in high temperature environments. It is therefore our instruction that the user must always err on the side of caution and make ample provisions for reduced Working Load Limits. The following are our instructions:

ACIDIC CONDITIONS

Beaver Alloy Grade T(80) slings shall not be used in acidic solutions or in any other corrosive environment.

GALVANISING

Beaver alloy chains and fittings should not be hot-dip galvanised or electro-plated, except by Beaver. Galvanised slings must always have the Working Load Limits reduced by 20%.

The W.L.L. of a sling must not exceed the lowest working load limit of the components in the system.

Grade ‘S’ or ‘6’ Shackles

WORKING LOAD LIMIT Metric Tonnes DIA. d mm DIA. PIN D mm INSIDE WIDTH W mm

WITH YELLOW PAINTED PIN TO AS2741-2002

INSIDE LENGTH DEE TYPE BOW TYPE L L mm mm

WIDTH OF BOW B mm

APPROX. WEIGHT EACH SCREW SAFETY PIN PIN kg kg

Beaver Dee Shackle with Screw Pin

Ød L ØD W B Ød

0.33 0.50 0.75 1.00 1.50 2.00 3.20 4.70 6.50 8.50 9.50 12.00 13.50 17.00 25.00 35.00 45.00 55.00 85.00 120.00 150.00

5 6 8 10 11 13 16 19 22 25 29 32 35 38 44 51 57 63 76 89 102

6 8 10 11 13 16 19 22 25 29 32 35 38 41 51 57 63 70 83 95 108

10 12 13 17 18 21 27 32 37 43 46 52 57 60 73 83 95 105 127 146 165

— 22 26 32 37 41 51 60 71 81 90 100 113 124 146 171 181 203 229 267 318

22 29 31 37 43 48 61 72 84 95 108 119 133 146 178 197 222 267 330 381 432

15 20 21 26 29 33 43 51 58 68 74 83 92 98 127 146 160 184 200 241 279

0.02 0.06 0.11 0.15 0.21 0.37 0.65 1.06 1.56 2.32 3.28 4.51 5.43 7.89 13.40 18.85 26.06 37.86 58.68 — —

— 0.07 0.13 0.17 0.25 0.44 0.79 1.26 1.88 2.78 3.87 5.26 6.94 8.79 14.99 20.65 29.01 41.05 62.24 110.00 160.00

Beaver Bow Shackle with Screw Pin

L ØD W

Ød

Beaver Safety Dee Shackle Bolt Type

L ØD W B Ød

Beaver Safety Bow L Shackle Bolt Type ØD

W

OTHER SIZES UP TO 1000 TONNES AVAILABLE ON REQUEST

Polyester Round Slings & Flat Webbing Slings

ROUND SLINGS MANUFACTURED TO AS4497.1-1997

ROUND SLINGS Comply to AS 4497.1-1997

FLAT SLINGS MANUFACTURED TO AS1353.1-1997

All Beaver Flat and Round Slings are fully tested. Test Certificates supplied with all slings. ROUND SLINGS BEAVER CODE FLAT SLING BEAVER CODE

FLAT SLINGS Comply to AS 1353.1-1997

L = LOAD FACTOR COLOUR CODE W.L.L. Tonnes

L = 1.0 VERTICAL W.L.L. Tonnes

L = 0.8 CHOKE S.W.L. Tonnes

L = 2.0 BASKET S.W.L. Tonnes

L = 1.7 60° S.W.L. Tonnes

L = 1.4 90° S.W.L. Tonnes

L = 1.0 120° S.W.L. Tonnes

L = 1.7 60° S.W.L. Tonnes

L = 1.38 60° CHOKE S.W.L. Tonnes

MRS1000 MRS2000 MRS3000 MRS4000 MRS5000 MRS6000 MRS8000 MRS10000

FS-2-1000 Violet FS-2-2000 Green FS-2-3000 Yellow FS-2-4000 Grey FS-2-5000 Red FS-2-6000 Brown FS-2-8000 Blue FS-2-10000 Orange

1.0 2.0 3.0 4.0 5.0 6.0 8.0 10.0

1.0 2.0 3.0 4.0 5.0 6.0 8.0 10.0

0.8 1.6 2.4 3.2 4.0 4.8 6.4 8.0

2.0 4.0 6.0 8.0 10.0 12.0 16.0 20.0

1.73 3.46 5.19 6.92 8.65 10.38 13.84 17.30

1.41 2.82 4.23 5.63 7.05 8.46 11.28 14.10

1.0 2.0 3.0 4.0 5.0 6.0 8.0 10.0

1.73 3.46 5.19 6.92 8.65 10.38 13.84 17.30

1.38 2.76 4.14 5.52 6.90 8.28 11.04 13.80

© Copyright Beaver Brands Pty Limited July 2012 BØC-SA-01-003-B

The information contained within the above tables is taken from the relevant Australian Standards and was correct at the time of publication.

LIFTING I RIGGING I LOAD RESTRAINTS I FALL PREVENTION I PERSONAL PROTECTIVE EQUIPMENT I INDUSTRIAL FOOTWEAR | 4WD RECOVERY I LIFTING I RIGGING I LOAD RESTRAINTS I FALL PREVENTION I PERSONAL PROTECTIVE EQUIPMENT I INDUSTRIAL FOOTWEAR | 4WD RECOVERY I LIFTING I RIGGING I LOAD RESTRAINTS I FALL PREVENTION I PERSONAL PROTECTIVE EQUIPMENT I INDUSTRIAL FOOTWEAR | 4WD RECOVERY

340

www.synergysystems.com.au