- Page 1

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Page 213

- Page 214

- Page 215

- Page 216

- Page 217

- Page 218

- Page 219

- Page 220

- Page 221

- Page 222

- Page 223

- Page 224

- Page 225

- Page 226

- Page 227

- Page 228

- Page 229

- Page 230

- Page 231

- Page 232

- Page 233

- Page 234

- Page 235

- Page 236

- Page 237

- Page 238

- Page 239

- Page 240

- Page 241

- Page 242

- Page 243

- Page 244

- Page 245

- Page 246

- Page 247

- Page 248

- Page 249

- Page 250

- Page 251

- Page 252

- Page 253

- Page 254

- Page 255

- Page 256

- Page 257

- Page 258

- Page 259

- Page 260

- Page 261

- Page 262

- Page 263

- Page 264

- Page 265

- Page 266

- Page 267

- Page 268

- Page 269

- Page 270

- Page 271

- Page 272

- Page 273

- Page 274

- Page 275

- Page 276

- Page 277

- Page 278

- Page 279

- Page 280

- Page 281

- Page 282

- Page 283

- Page 284

- Page 285

- Page 286

- Page 287

- Page 288

- Page 289

- Page 290

- Page 291

- Page 292

- Page 293

- Page 294

- Page 295

- Page 296

- Page 297

- Page 298

- Page 299

- Page 300

- Page 301

- Page 302

- Page 303

- Page 304

- Page 305

- Page 306

- Page 307

- Page 308

- Page 309

- Page 310

- Page 311

- Page 312

- Page 313

- Page 314

- Page 315

- Page 316

- Page 317

- Page 318

- Page 319

- Page 320

- Page 321

- Page 322

- Page 323

- Page 324

- Page 325

- Page 326

- Page 327

- Page 328

- Page 329

- Page 330

- Page 331

- Page 332

- Page 333

- Page 334

- Page 335

- Page 336

- Page 337

- Page 338

- Page 339

- Page 340

- Page 341

- Page 342

- Page 343

- Page 344

- Page 345

- Page 346

- Page 347

- Page 348

- Page 349

- Page 350

- Page 351

- Page 352

- Page 353

- Page 354

- Page 355

- Page 356

- Page 357

- Page 358

- Page 359

- Page 360

- Page 361

- Page 362

- Page 363

- Page 364

- Page 365

- Page 366

- Page 367

- Page 368

- Page 369

- Page 370

- Page 371

- Page 372

- Flash version

© UniFlip.com

- Page 2

- Page 3

- Page 4

- Page 5

- Page 6

- Page 7

- Page 8

- Page 9

- Page 10

- Page 11

- Page 12

- Page 13

- Page 14

- Page 15

- Page 16

- Page 17

- Page 18

- Page 19

- Page 20

- Page 21

- Page 22

- Page 23

- Page 24

- Page 25

- Page 26

- Page 27

- Page 28

- Page 29

- Page 30

- Page 31

- Page 32

- Page 33

- Page 34

- Page 35

- Page 36

- Page 37

- Page 38

- Page 39

- Page 40

- Page 41

- Page 42

- Page 43

- Page 44

- Page 45

- Page 46

- Page 47

- Page 48

- Page 49

- Page 50

- Page 51

- Page 52

- Page 53

- Page 54

- Page 55

- Page 56

- Page 57

- Page 58

- Page 59

- Page 60

- Page 61

- Page 62

- Page 63

- Page 64

- Page 65

- Page 66

- Page 67

- Page 68

- Page 69

- Page 70

- Page 71

- Page 72

- Page 73

- Page 74

- Page 75

- Page 76

- Page 77

- Page 78

- Page 79

- Page 80

- Page 81

- Page 82

- Page 83

- Page 84

- Page 85

- Page 86

- Page 87

- Page 88

- Page 89

- Page 90

- Page 91

- Page 92

- Page 93

- Page 94

- Page 95

- Page 96

- Page 97

- Page 98

- Page 99

- Page 100

- Page 101

- Page 102

- Page 103

- Page 104

- Page 105

- Page 106

- Page 107

- Page 108

- Page 109

- Page 110

- Page 111

- Page 112

- Page 113

- Page 114

- Page 115

- Page 116

- Page 117

- Page 118

- Page 119

- Page 120

- Page 121

- Page 122

- Page 123

- Page 124

- Page 125

- Page 126

- Page 127

- Page 128

- Page 129

- Page 130

- Page 131

- Page 132

- Page 133

- Page 134

- Page 135

- Page 136

- Page 137

- Page 138

- Page 139

- Page 140

- Page 141

- Page 142

- Page 143

- Page 144

- Page 145

- Page 146

- Page 147

- Page 148

- Page 149

- Page 150

- Page 151

- Page 152

- Page 153

- Page 154

- Page 155

- Page 156

- Page 157

- Page 158

- Page 159

- Page 160

- Page 161

- Page 162

- Page 163

- Page 164

- Page 165

- Page 166

- Page 167

- Page 168

- Page 169

- Page 170

- Page 171

- Page 172

- Page 173

- Page 174

- Page 175

- Page 176

- Page 177

- Page 178

- Page 179

- Page 180

- Page 181

- Page 182

- Page 183

- Page 184

- Page 185

- Page 186

- Page 187

- Page 188

- Page 189

- Page 190

- Page 191

- Page 192

- Page 193

- Page 194

- Page 195

- Page 196

- Page 197

- Page 198

- Page 199

- Page 200

- Page 201

- Page 202

- Page 203

- Page 204

- Page 205

- Page 206

- Page 207

- Page 208

- Page 209

- Page 210

- Page 211

- Page 212

- Page 213

- Page 214

- Page 215

- Page 216

- Page 217

- Page 218

- Page 219

- Page 220

- Page 221

- Page 222

- Page 223

- Page 224

- Page 225

- Page 226

- Page 227

- Page 228

- Page 229

- Page 230

- Page 231

- Page 232

- Page 233

- Page 234

- Page 235

- Page 236

- Page 237

- Page 238

- Page 239

- Page 240

- Page 241

- Page 242

- Page 243

- Page 244

- Page 245

- Page 246

- Page 247

- Page 248

- Page 249

- Page 250

- Page 251

- Page 252

- Page 253

- Page 254

- Page 255

- Page 256

- Page 257

- Page 258

- Page 259

- Page 260

- Page 261

- Page 262

- Page 263

- Page 264

- Page 265

- Page 266

- Page 267

- Page 268

- Page 269

- Page 270

- Page 271

- Page 272

- Page 273

- Page 274

- Page 275

- Page 276

- Page 277

- Page 278

- Page 279

- Page 280

- Page 281

- Page 282

- Page 283

- Page 284

- Page 285

- Page 286

- Page 287

- Page 288

- Page 289

- Page 290

- Page 291

- Page 292

- Page 293

- Page 294

- Page 295

- Page 296

- Page 297

- Page 298

- Page 299

- Page 300

- Page 301

- Page 302

- Page 303

- Page 304

- Page 305

- Page 306

- Page 307

- Page 308

- Page 309

- Page 310

- Page 311

- Page 312

- Page 313

- Page 314

- Page 315

- Page 316

- Page 317

- Page 318

- Page 319

- Page 320

- Page 321

- Page 322

- Page 323

- Page 324

- Page 325

- Page 326

- Page 327

- Page 328

- Page 329

- Page 330

- Page 331

- Page 332

- Page 333

- Page 334

- Page 335

- Page 336

- Page 337

- Page 338

- Page 339

- Page 340

- Page 341

- Page 342

- Page 343

- Page 344

- Page 345

- Page 346

- Page 347

- Page 348

- Page 349

- Page 350

- Page 351

- Page 352

- Page 353

- Page 354

- Page 355

- Page 356

- Page 357

- Page 358

- Page 359

- Page 360

- Page 361

- Page 362

- Page 363

- Page 364

- Page 365

- Page 366

- Page 367

- Page 368

- Page 369

- Page 370

- Page 371

- Page 372

- Flash version

© UniFlip.com

Has good resistance to cyclic and dynamic loading. Resists loosening under vibration. Indicates the suitability of product to specific types of performance related situations. Suitable for an effective pull-down feature, Anchor has elevated temperate applications. Structural anchor components ability to clamp Has good resistance to cyclic and dynamic or is a stud anchor. It has the made from steel. Any plastic or the base material and provide loading. Resists loosening under vibration. the fixture to non-ferrous parts make no contribution to holding power under elevated temperatures. high resistance to cyclic loading.

PERFORMANCE RELATED SYMBOLS

ChemSet 101 Plus, StructaSet™401™ & REO502™

Anchor has an effective pull-down feature, or is a stud anchor. It has the ability to clamp the fixture to the base material and provide high resistance to cyclic loading.

™

May be used close to edges (or another Suitable for use in seismic design. anchor) without risk of splitting the concrete.

Suitable for use in seismic design.

Cracked concrete. Temporary or removable anchor.

MATERIAL SPECIFICATION SYMBOLS

Indicates the base material and surface finish to assist in selection with regard

Cracked concrete.

Steel Zinc Plated to AS1791-1986. Minimum thickness 6 micron. Recommended for internal applications only. Indicates the base material and surface finish to assist in selection with regard to corrosion or environmental issues.

MATERIAL SPECIFICATION SYMBOLS

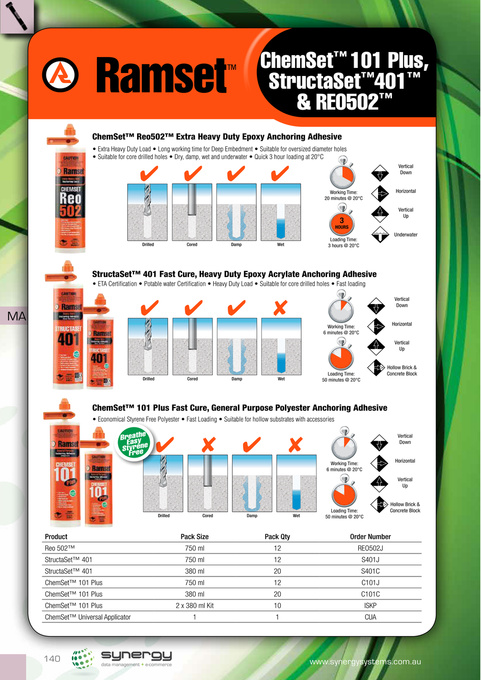

ChemSet™ Reo502™ Extra Heavy Duty Epoxy Anchoring Adhesive

• Extra Heavy Duty Load • Long working time for Deep Embedment • Suitable for • Suitable for core drilled holes • Dry, damp, wet and underwater • Quick 3 hour loading at 20°C

Steel Zinc Plated to AS1791-1986. Minimum thickness 6 micron. Recommended for internal applications only.

SteelGradeDipped Galvanised to AS1650-1989 AISI Hot 316 Stainless Steel, resistant to corrosive and AS1214-1983. agents including chlorides and industrial pollutants. Minimum thickness 42 micron. Recommended for internal or external PERFORMANCE RELATED SYMBOLS applications

HCR

For of product to specific types of in marine or applications. Indicates the suitabilityexternal corrosive environments. performance related situati

Steel Hot Dipped Galvanised to AS1650-1989 and AS1214-1983. Minimum thickness 42 micron. oversized diameter holes For external applications.

HCR

Has good resistance to cyclic and resistance. Stainless Steel High Corrosion dynamic loading.Grade 1.4529/1.4565. vibration. HCR Resists loosening under

INSTALLATION has an effective pull-down feature, Anchor RELATED SYMBOLS

Indicates the or is a stud anchor. It has the ability to clamp requirements. suitable positioning and other installation related Corrosion resistant. theNotVertical basefor direct exposure to sunlight. fixture to the recommended material and provide high resistancefloor applications. Suitable for to cyclic loading.

4

4

4

4

Down

INSTALLATION RELATED SYMBOLS

Indicates the suitable positioning and other installation related requirements. Suitable for use in seismic design.

Working Time: Suitable for floor applications.

20 minutes @ 20°C

Horizontal Chemical anchors suitable for Suitable for wall applications. use in dry holes. Vertical Chemical anchors suitable for use Suitable for overhead applications.in damp holes. Up MATERIAL SPECIFICATION SYMBOLS

Steel Zinc Plated to AS1791-1986.and hollow Chemical anchors brick/block Suitable for hollowsuitable for use in holes Underwater Minimum thickness 6 micron. filled with water. core concrete applications. Recommended for internal applications only. Cracked concrete.

Suitable for wall applications.

Indicates the base material and surface finish to assist in selection with regard to Suitable for overhead applications.

Drilled

Cored

Damp

Wet

Loading Time: 3 hours @ 20°C

Suitable for hollow brick/block and hollow core concrete applications.

Anchor can be through fixed into substrate StructaSet™ 401 Fast Cure, Heavy Duty Epoxy Acrylate Anchoring Adhesive using fixture as template.

• ETA Certification • Potable water Certification • Heavy Duty Load • Suitable for core drilled holes • Fast loading

Steel Hot Dipped Galvanised to AS1650-1989 Anchor can be through fixed into and AS1214-1983. in drilled holes. substrate Suitable for use using fixture as template. HCR Minimum thickness 42 micron. PERFORMANCE RELATED SYMBOLS For external applications. Indicates the suitability of product to specific types of performance related situ Suitable for AAC and lightweight concrete Suitable for use in cored holes. applications. Has good resistance to cyclic and dynamic loading. Resists loosening under vibration.

INSTALLATION RELATED SYMBOLS

MA

4

4

4

✘

Suitable for AAC and lightweight concrete applications.

Suitable for contact with drinking water Indicates the suitable positioning and otherpull-down feature, requirements. Anchor has an effective installation related for a stud anchor. It has or ishuman consumption the ability to clamp Vertical the fixture to the base material and provide Suitable for floor applications. Down high resistance to cyclic loading.

Working Time: 6 minutes @ 20°C

Suitable for use in seismic design. Horizontal Suitable for wall applications.

Up MATERIAL SPECIFICATION SYMBOLS

Cracked concrete. Vertical Suitable for overhead applications.

Drilled

Cored

Damp

Wet

Loading Time: 50 minutes @ 20°C

Indicates the base material and surface finish to assist in selection with regard Suitable for Hollow Zinchollow brick/block and hollow Steel Brick & core concretePlated to AS1791-1986. applications. Minimum thickness Concrete Block 6 micron. Recommended for internal applications only. Anchor can be through fixed into substrate Steel Hot Dipped Galvanised to AS1650-1989 using fixture as template. and AS1214-1983. Minimum thickness 42 micron. For external applications. Suitable for AAC and lightweight concrete applications.

HCR

ChemSet™ 101 Plus Fast Cure, General Purpose Polyester Anchoring Adhesive

• Economical Styrene Free Polyester • Fast Loading • Suitable for hollow substrates with accessories

INSTALLATION RELATED SYMBOLS

h Breaty e Eas ne e Styree Fr

Indicates the suitable positioning and other installation related requirements.

4

✘

4

✘

Working Time: 6 minutes @ 20°C Loading Time: 50 minutes @ 20°C

Vertical

Suitable for floor applications. Down

Horizontal Suitable for wall applications. Vertical Up

Suitable for overhead applications.

Drilled

Cored

Damp

Wet

Suitable Hollow for hollow brick/block and hollow Brick & core concrete applications. Concrete Block

Anchor can be through fixed into substrate using fixture as template.

Product Reo 502™ StructaSet™ 401 StructaSet™ 401 ChemSet™ 101 Plus ChemSet™ 101 Plus ChemSet™ 101 Plus ChemSet™ Universal Applicator

Pack Size 750 ml 750 ml 380 ml 750 ml 380 ml 2 x 380 ml Kit 1

Pack Qty 12 12 20 12 20 10 1

Order Number REO502J S401J S401C C101J C101C ISKP CUA

Suitable for AAC and lightweight concrete applications.

140

www.synergysystems.com.au