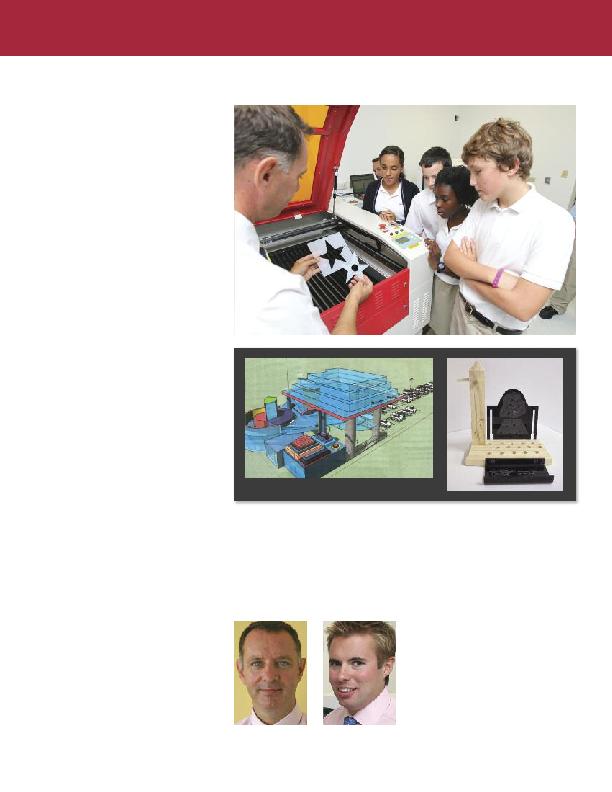

ment are giving students a taste of life

as 21st-century engineers.

of a laser cutter able to produce two-

dimensional work and a Denford

Router 2600 Pro for cutting a range of

resistant materials such as wood, plastic,

modelling foam and acrylic to produce

3D work. The purchase--funded by

longtime Trustee Charlie Marshall--

opens up a world of hands-on

computer-aided design (CAD) and

computer-aided manufacturing (CAM)

experience to Secondary students--at a

time when global economies are crying

out for technology-skilled engineers,

architects and industrial designers,

according to DT Head Phillip Heap.

turing technologies, employers recognise

the workforce needs to be adaptive,

creative, analytical and highly competent

with computer programs," he says.

"over the past two years, Design Tech-

nology at Saltus has been transformed

into a high-tech department which can

deliver those skills necessary to give

students a leading edge for future

college careers and employment."

access to CAD/CAM manufacturing--

the same computer software used by the

automotive, aerospace and industrial

design industries to create technical

drawings and control machines to

manufacture products. From Years 7 to

SGY, students use a variety of CAD

software such as Google SketchUp,

Techsoft's 2D Design, Solidworks and

Pro/DESKToP to help create imaginative

ideas. Now they can also output their

industrial artworks as tangible work-

pieces. "Previously, they couldn't export

says. "Thanks to the generous donation,

they can manufacture their designs

through the latest CAM equipment."

keting, designing with CAD, planning

and construction techniques to create

products. "Students use 2D Techsoft to

produce their work," Mr. Heap explains.

"They import bitmap images from the

web and then vectorise them into

diagrams so the laser cutter can identify

what is to be engraved and cut."

year, Design Technology is today

considered a highly academic subject,

with students able to take it all the way

to A-Level and university programmes

--a trend Western design and manufac-

turing industries are driving to keep

pace with competition from China,

Singapore and other tiger economies.

A