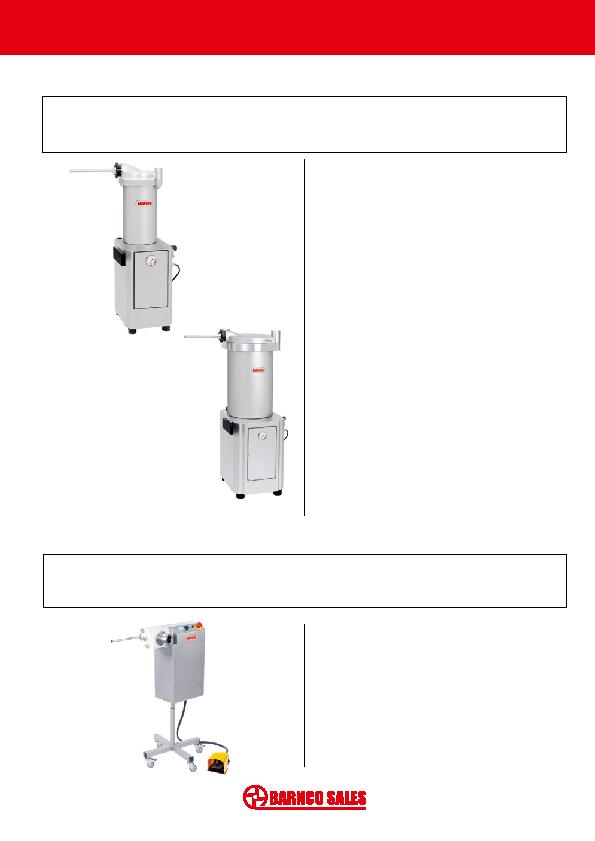

Approximatepistoncapacities:

EC-12:12Litres/+10Kg.

EM-20:20Litres/+18Kg.

EM-30:30Litres/+28Kg.

EM-50:50Litres/+48Kg.

Motors:III:230/400V,50Hz/II:230V,50Hz

Distancefromfloortonozzle:

EC-12:1,000mm

EM-20:1,055mm

EM-30:1,150mm

EM-50:1,206mm

Overall dimensions:

EC-12:47x41x106cm

EM-20:47x41x111cm

EM-30:50x47x121cm

EM-50:54x54x125cm

All single phase motors are equipped with a fan kit as

standard.

The 3 phase motors may also be equipped with a fan kit as

anoption(V).

OnlytheEM-50isequippedwiththefankitin both single

and 3 phase as standard.

pressure gauge. The machines come as standard with 3 stainless steel nozzles of 15, 20 and 30 mm Ø. Optional nozzles of 12,

25 and 43 mm Ø.

Portioncapacity:+ 20g - + 215g

Distancefromfunneltofloor:

Same as the sausage filler connected to it.

Motors: II:230V,50Hz

Overall dimensions:

79x53x109cm

complete with motor and electrical panel. Semi-automatic and automatic operation with timer to regulate working speed.

Equippedwith3stainlesssteelnozzlesof12,15and20mmØ.Capableoftwistingediblecollagencasing.