6

GA

/ Vol. 5 / No.4 / APRIL 2013

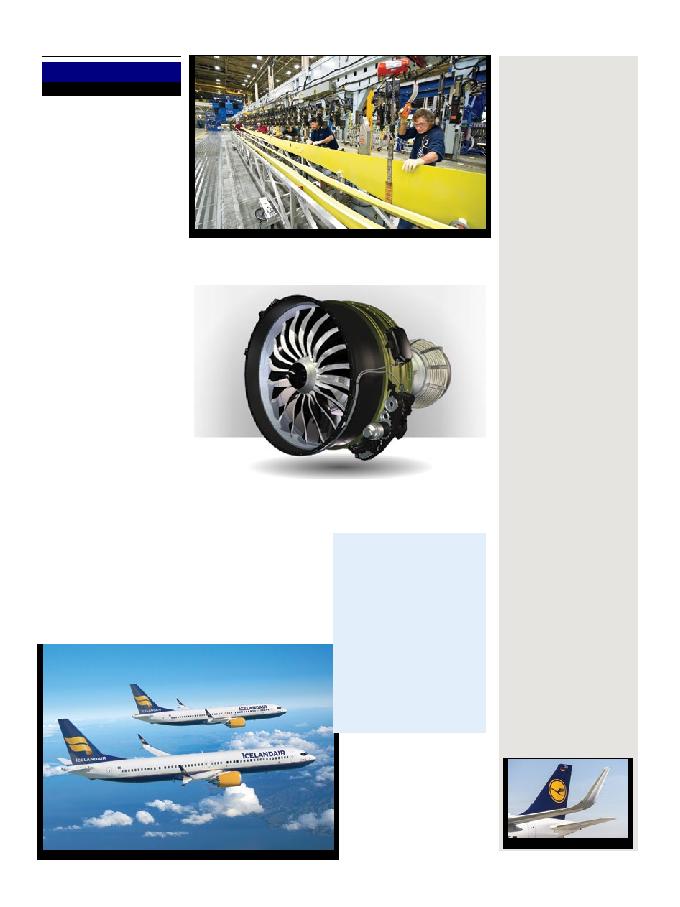

Boeing is now building the first Next-Generation 737 at the rate of 38 airplanes per

month. Over the past two years, production of the 737 has risen more than 20 percent,

from 31.5 to 38 airplanes a month. Pictured here, mechanics load initial parts of

the spars for the first airplane at the new rate into a spar-assembly machine.

Airline Industry

On February 13, 2013 Boeing and

Icelandair announced a firm order for

16 737 MAX airplanes valued at more

than $1.6 billion at list prices. The order,

originally announced as a commitment for

12 airplanes in December 2012, has been

increased to 16 airplanes and includes

737 MAX 8s and 9s, as well as purchase

rights for eight additional 737 MAXs.

Shown here is an artist rendition of the

MAX 8 and MAX 9 in Icelandair livery.

Breakthrough

Performance advancements are driven

by appropriate application of new

technology throughout an engine.

Success in development of new tech-

nology requires the combination of

both consistent investment and oppor-

tunities for commercial application.

Two engine families have

contributed significantly to the design

of the LEAP engine, the CFM56 and

the GE90/GEnx series of engines.

The GE90/GEnx contributed the

high-efficiency core architecture

to minimize fuel consumption,

while the CFM56 legacy drove

reliability and maintenance cost

design practices. At entry into

service in 2017, it is estimated that

the GE90/GEnx architecture will

have generated 80 million flight

hours of revenue service, while the

CFM56 family will have over 700

million flight hours of experience.

The LEAP engine family offers

proven, material advantages over

any other engine, with 550,000 hours

of proven experience with 99.98%

reliability, and 22,000 engines

delivered on-time and on-spec.

The CFM LEAP pedigree ensures

with confidence the ability to deliver

a 15% improvement in fuel efficiency,

as compared to the CFM56-7BE,

while maintaining the same level

of dispatch reliability and life-cycle

maintenance costs as the CFM56-

7BE. With its simple architecture

and $2 billion annual investment in

technology, the LEAP engine family

LEAP

Turbofan Engine

Leap-1A 24,500 32,900 pounds thrust

Leap-1B 20,000 28,000 pounds thrust

Leap-1C 27,980 30,000 pounds thrust

The CFM LEAP-1B is the exclusive powerplant for the Boeing 737 MAX family

of single-aisle aircraft (737 MAX-7, 737 MAX-8, 737 MAX-9). This engine has

been optimized to provide the 737 MAX the best possible fuel efficiency while

maintaining the reliability and maintenance cost legacy of the CFM56 family.

Did you know?

· LEAP's angled high-pressure turbine

blade tip squealer generates an aerody-

namic vena contracta to reduce leakage

and improve turbine efficiency.

· LEAP's high-pressure turbine blade coun-

ter tip baffle airfoil reduces aerodynamic

loss in the turbine and improves engine

fuel burn. LEAP's non axi-symmetric

airfoil bands and platforms limit secondary

flow to reduce pressure loss and improve

engine fuel burn.

· LEAP's nested ball/roller for core bearing

spring finger reduces sump volume

and increases engine by-pass ratio.

· LEAP's high-pressure compressor airfoil

design with rotor radial camber distribu-

tion improves compressor stage throttle

margin.

offers the lowest cost and highest

revenue-generating ability, saving an

estimated nearly $3 million per plane.

This is CFM, proven

performance, low execution

risk, and the application of

advanced technology both at

entry into service and throughout

an engine's life cycle. ·

Boeing subsidiary

unveils tool to

improve testing of

wireless networks

Boeing, a subsidiary Digital

Receiver Technology Inc. (DRT)

debuted an easier, faster way for

wireless carriers and infrastructure

providers to assess their cellular

network and identify areas where

upgrades may be required.

Unveiled during the 2013

Mobile World Congress in

Barcelona, the pocket-sized

DRT4311B could ultimately help

increase network performance

and customer satisfaction.

"The unit's Software Defined

Radio architecture and wideband

receiver allow operators to use

the same device to measure

multiple frequency bands

without changing hardware

increasing their productivity and

reducing cost. The platform's

low power consumption and

lightweight design make it

even more affordable and

adaptable according to DRT.

The DRT4311B can

simultaneously scan between

2G, 3G and 4G networks

with a wireless control

application that is compatible

with any Android device. ·

Lufthansa takes

delivery of it first

Airbus A320 equipped

with Sharklets

Lufthansa has taken delivery

of its first A320 equipped with

Sharklets at the Airbus site in

Hamburg, Germany. Lufthansa

is became the first carrier in

Europe to take advantage of the

new fuel-saving wing-tip devices.

The airline will receive 21 more

A320 Family aircraft equipped

with Sharklets until 2015.

Sharklets are made from

light-weight composites and are

2.4 meters tall. They are an option

on new-build A320 Family aircraft

and standard on all members of

the new A320neo family. They

offer operators up to four percent

fuelburn reduction on longer range

sectors and provide the flexibility

of either adding an additional

100 nautical miles range or

increased payload capability

of up to 450 kilograms. ·