2013 APRIL / Vol. 5 / No. 4 /

GA

15

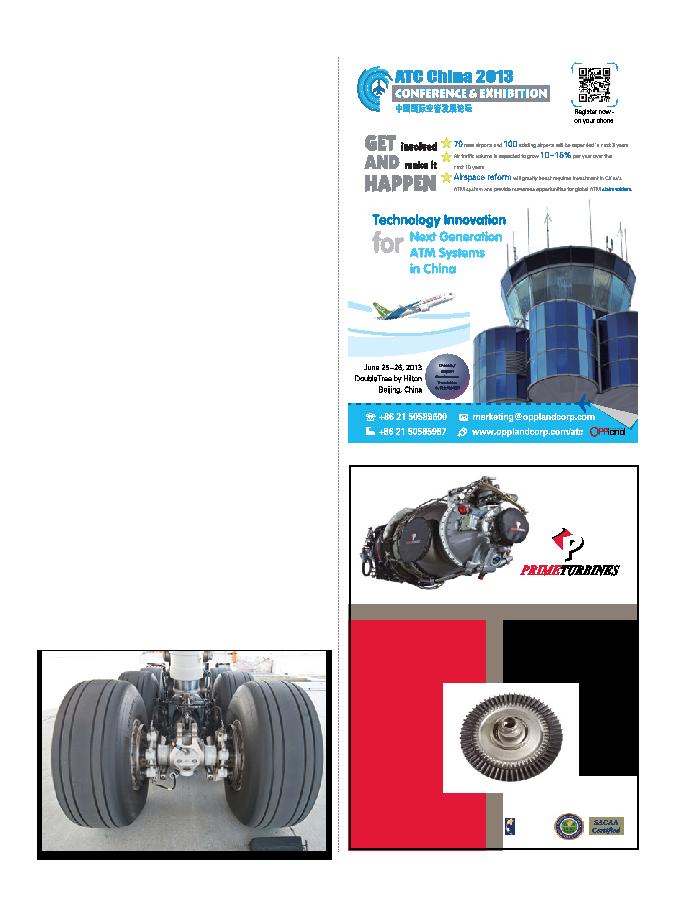

rim supports the tire's profile.

Sidewall and shoulder

The sidewall is that part of the tire

that bridges between the tread

and bead. The sidewall is largely

rubber but reinforced with fabric

or steel cords that provide for

tensile strength and flexibility.

The sidewall contains air pressure

and transmits the torque applied

by the drive axle to the tread to

create traction but supports little

of the weight of the vehicle, as is

clear from the total collapse of the

tire when punctured. Sidewalls are

molded with manufacturer-specific

detail, government mandated

The shoulder is that part of the

tyre at the edge of the tread as it

makes transition to the sidewall.

Ply

Plies are layers of relatively

inextensible cords embedded in

the rubber to hold its shape by

preventing the rubber from stretching

in response to the internal pressure.

Aircraft tyres are designed to

withstand extremely heavy loads

for short durations. The number

of tyres required for aircraft

increases with the weight of the

plane (because the weight of the

airplane has to be distributed

better). Aircraft tyre tread patterns

are designed to facilitate stability

in high crosswind conditions, to

channel water away to prevent

hydroplaning, and for braking effect.

Aircraft tyres are usually

inflated with nitrogen or helium

to minimize expansion and

contraction from extreme changes

in ambient temperature and pressure

experienced during flight. Dry

nitrogen expands at the same rate

as other dry atmospheric gases, but

common compressed air sources

may contain moisture, which

increases the expansion rate with

temperature. Aircraft tires generally

operate at high pressures, up to

200 pounds per square inch (14

bar; 1,400 kPa) for airliners, and

even higher for business jets.

Tests on aircraft tyres have

shown that they are able to sustain

pressures of maximum 800 pounds

per square inch (55 bar; 5,500 kPa)

before bursting. During the test the

tyres have to be filled with water,

instead of helium or nitrogen,

which is the common content of

aircraft tyres, to prevent the test

room being blown apart by the

energy when the tyre bursts.

Aircraft tyres also include heat

fuses, designed to melt at a certain

temperature. Tires often overheat if

maximum braking is applied during

an aborted takeoff or an emergency

landing. The fuses provide a

safer failure mode that prevents

tire explosions by deflating in a

controlled manner, thus minimizing

damage to aircraft and objects in

the surrounding environment.

The requirement that an inert gas,

such as nitrogen, be used instead of

air for inflation of tires on certain

transport category airplanes was

prompted by at least three cases in

which the oxygen in air-filled tires

combined with volatile gases given

off by a severely overheated tire and

exploded upon reaching autoignition

temperature. The use of an inert

gas for tire inflation will eliminate

the possibility of a tire explosion.

Auto braking

An aircrafts auto braking and anti

skid systems are designed to slow

the machine down at a constant rate

given the runway still available.

In this way the brakes and tyres

are saved. Most passenger aircraft

have reverse thrust and spoilers

to aid this process. The latest

systems on the newest products

include BTV brake to vacate

you program a vacate taxiway into

the electronic flight bag and the

systems through the auto braking

deploy optimal braking so as to

bring the aircraft to a smooth stop

by the particular taxiway selected

by the flight crew. This saves on

tyre wear and time on the runway. ·

It's Your Choice...

Prime Turbines is an

independent, FAA authorized

overhaul facility. We're not

confined to the OEM's limiting

policies, and you shouldn't be

either. You deserve to choose

your MRO facility and find

value-saving alternatives.

From fuel nozzle flow to

engine overhaul, Prime

Turbines gives you the

options you need. Each engine

is different, which is why we

are dedicated to serving your

individual needs.

Explore the alternatives...

call Prime Turbines.

ENGINE OVERHAUL

POWER SECTION

ENGINE TESTING

HOT SECTION

GAS GENERATOR

FUEL NOZZLES

M.O.R.E.

PROGRAM

BLEED VALVE

www.primeturbines.com

PT6A Repair & Overhaul

Fernand Foisy

ffoisy@primeturbines.com

Mobile: +27 8573 9842

EASA