12

GA

/ Vol. 5 / No.4 / APRIL 2013

by Dainius Sakalauskas, Deputy Head of

FL Technics Training

Airline News

As air operators seek to streamline

their avenues of expenditure,

increasing attentiona is being paid to

the role of knowledge engineering

in high frequency maintenance of

aircraft parts and components. In line

with this, a recently published study

commissioned by Susana Ferreiro,

a computer engineer of Donostia-

San Sebastián, addressed several

factors of assistance to air operators

in reducing their maintenance costs

and improving air safety in the

long term. The research focused on

high frequency maintenance issues

including the degradation of aircraft

brakes, the appearance of burrs during

the manufacture of components and

the deterioration of oil quality used

in lubrication. The results of the

study provide topical value to fleet

managers seeking to optimise their

maintenance expenditures while

offering sound reasoning in support

The role of knowledge

engineering to improve

aircraft maintenance

of improved standards of flight safety.

Irrespective of the fleet scope,

maintenance costs routinely account for

anywhere between 10 and 45 percent

of annual operating expenses. In any

case, this equates to a substantial outlay

for air operators. As no reasonable

fleet manager would permit a drop in

maintenance standards in an effort to

reduce costs, many are turning to the

role played by knowledge engineering

in order to sustain a healthy level

of competitiveness. This study was

interesting from the point of view

that it applied techniques based on

artificial intelligence, data mining and

machine learning to enhance certain

elements of aircraft maintenance.

Although it is too early to tell whether

this study will hold a major bearing

on changes to aircraft maintenance

practices, we are always open to new

ideas aimed at addressing lingering

problems within the aviation industry.

Managing brake wear limits for

aircraft landing gear entails routine

line inspections of the assembly.

Organised as part of the European

TATEM project for increasing aircraft

operability by managing the time and

cost outlay for scheduled maintenance,

the study made use of algorithms

to model solutions to the predictive

maintenance of aircraft brake wear.

Specifically, the research looked into

estimating the wear of individual

brake components in order to plan

an effective allocation of resources.

This in turn would allow maintenance

to be deferred to optimal locations

(and times) as well as improve flight

punctuality by lessening delays

caused by corrective maintenance.

Additionally, the research sought

solutions to controlling the emergence

of burrs during the manufacture of

aircraft parts. As mandated by the

aviation industry, burrs (a material

edge disturbance often caused by

drilling) must not exceed 127 microns.

The study aimed to develop a process

whereby checks carried out for

material burrs could be optimised

by using the internal signals of a

drilling machine to detect in real

time when the burr limit has been

exceeded. The process routinely and

wholly applied to control material

burring could thus be applied

only when actually necessary.

Perhaps more notably however,

the research proposed a model for

detecting the extent of oil degradation

(used in component lubrication)

without the costly requirement for

laboratory testing. It focused on

spectrometric techniques to determine

the basicity of the oil and thereby

advise on its current state. As the

properties of oil deplete over time,

its monitoring is vital to ensure

effective lubrication of various aircraft

components. The method allows

for a sensor to be incorporated into

what is being monitored, making

expensive lab testing near redundant.

Improving aircraft maintenance

with a view to improved standards

in air safety is fundamental to all

involved in the industry. Indeed, over

time, errors made during routine line

and base maintenance have contributed

either directly or indirectly to almost

12 percent of airliner accidents

across the globe. While significant

improvements have been made in this

sector, such errors continue to impose

a financial burden on airlines on the

basis of unforeseen flight delays and

cancellations. It is therefore essential

for maintenance organisations to keep

abreast of changes aimed at improving

workplace practices in order to

ensure they remain competitive. ˇ

The first A350 XWB MSN001

now showing its completed wings,

has moved to its next phase of

ground testing, from Roger Béteille

A350 XWB FAL "Station 30" to

the Clément Ader area "Station

18" in Toulouse. The aircraft is

structurally complete and shows

the installed winglets, belly fairing

panels, main landing gear doors.

The aircraft has recently

completed successfully a series

of indoor ground tests including

stability tests on `movable' elements

such as rudder, elevators, ailerons

and wing spoilers and landing gears

extraction/retraction. The next steps

which will take place outdoors at

Station 18 will include three planned

families of tests: Fuel tanks testing

including levels, flows, sealing

and internal fuel transfer functions;

pressure testing of the fuselage;

and radio equipment testing. ˇ

First A350 XWB with wings complete emerges

for outdoor testing

hansel@doholdings.co.za

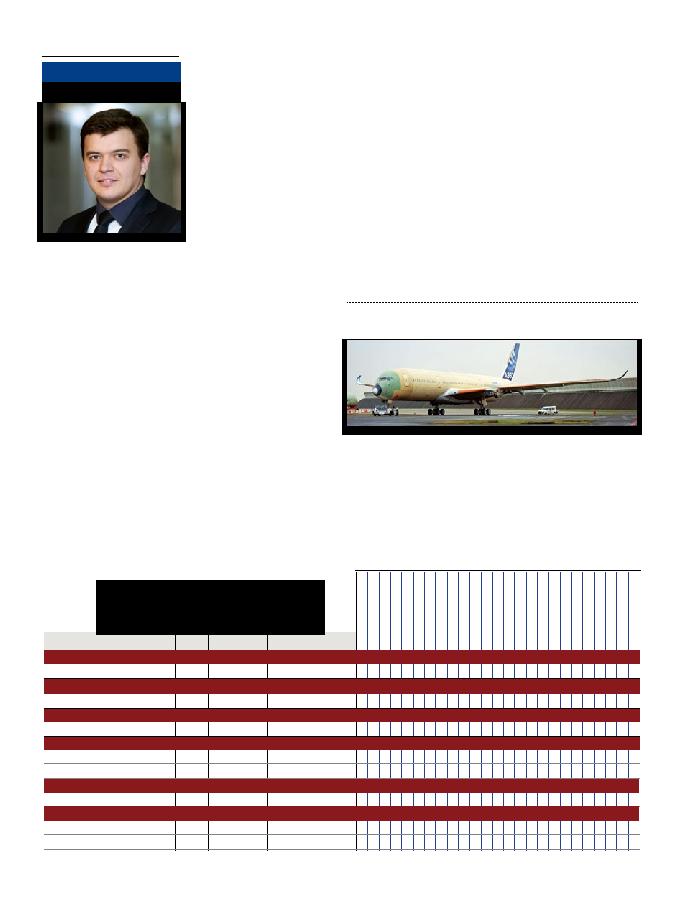

CHARTER

Companies - SA

Company

Code Telephone

E-mail

Virginia Airport - Durban

Rand Airport - Germiston

Grand Central - Midrand

Lanseria Airport

OR Tambo International - Johannesburg

KZN Aviation

Capital Air (Pty) Ltd

Jemax Aviation (Pty) Ltd

Swift Flight (Pty) Ltd

DO Charter

Federal Air Charters (Pty) Ltd & Bateleur Air Charter

Freedom Air

Powered Flight Charte

rs

031

011

011

011

011

011

012

078

564 6215

827 0335

805 0682

701 3298

659 2229

395 9000

751 1157

460 1231

mel@kznaviation.co.za

tanya@capitalairsa.com

fjoubert@jemaxaviation.co.za

info@swiftflite.co.za

hansel@doholdings.co.za

magda.baillie@fedair.com

info@freedomair.co.za

martin@poweredflight.co.za

< 20 Pax

> 20 pax

Biz J

ets

V

.I.P

.

Long-Range

Fr

eight

Helicopter

Special Ev

ents

Saf

er

o Char

ters

Contracts

Air

craft Sales

Sur

v

e

ys

Maintenance

Aerial Photogra

ph

y

Air

craft Leasing

Security Based (armed)

Line Inspections

Lodge T

ransf

ers

Expor

t Docs and Clearing

Hangarage

Air

craft Management

ˇ

ˇ ˇ ˇ ˇ

ˇ

ˇ

ˇ

ˇ

ˇ

ˇ ˇ ˇ ˇ

ˇ

ˇ

ˇ ˇ ˇ

ˇ

ˇ

ˇ ˇ

ˇ ˇ

ˇ

ˇ ˇ ˇ ˇ ˇ ˇ

ˇ ˇ

ˇ

ˇ

ˇ

ˇ

ˇ

ˇ ˇ

ˇ

ˇ

ˇ ˇ ˇ ˇ ˇ ˇ ˇ ˇ ˇ ˇ

ˇ ˇ

ˇ ˇ ˇ ˇ ˇ ˇ ˇ

ˇ

ˇ

ˇ ˇ ˇ ˇ ˇ ˇ

ˇ ˇ

ˇ ˇ

ˇ

Wonderboom airport - Pretoria