14

GA

/ Vol. 5 / No.4 / APRIL 2013

International Flight Clearances

Tel:

+27 76 983 1089

(24 hours)

Tel:

+27 11 701 2330/1

Fax:

+27 11 701 2334

Email:

flightops@flyifc.co.za

Website:

www.flyifc.co.za

Address:

Hanger 201, Gate 7 Ring Road, Lanseria

Airport. We are located in the Elite Jet Offices.

GPS coordinates:

S25

º 57.07 E27 º 58.1

We can get you anywhere!

Advert 21 Nov.indd 1

5/28/12 6:27 PM

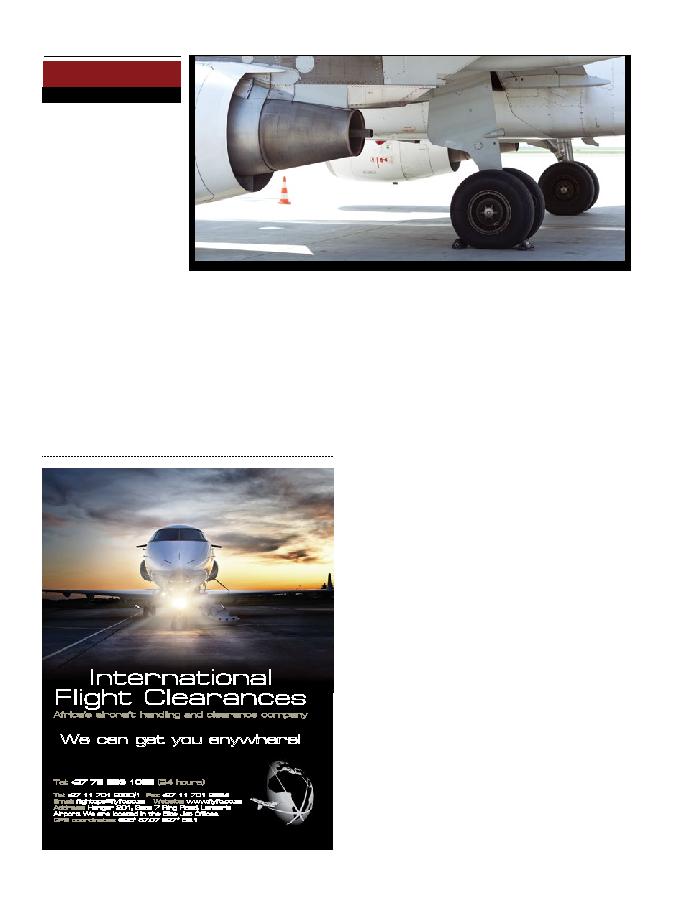

Aircraft Products

Aircaft tyres

Lets start off with a few general

comments re: tyres: Pneumatic tyres

are manufactured in about 450 tyre

factories around the world. Over

one billion tyres are manufactured

annually, making the tyre industry

a major consumer of natural rubber.

Tyre production starts with bulk

raw materials such as rubber,

carbon black, and chemicals and

produces numerous specialized

components that are assembled

and cured. Many kinds of rubber

are used, the most common being

styrene-butadene copolymer. This

article describes the components

assembled to make a tyre, the various

materials used, the manufacturing

processes and machinery.

Tread

The tread is the part of the tyre that

comes in contact with the road/

runway surface. The portion that is

in contact with the road at a given

instant in time is the contact patch.

The tread is a thick rubber, or rubber/

composite compound formulated

to provide an appropriate level of

traction that does not wear away

too quickly. The tread pattern is

characterized by the geometrical

shape of the grooves, lugs, voids and

sipes. Grooves run circumferentially

around the tire, and are needed

to channel away water. Lugs are

that portion of the tread design

that contacts the road surface.

Voids are spaces between lugs that

allow the lugs to flex and evacuate

water. Tread patterns feature non-

symmetrical (or non-uniform) lug

sizes circumferentially to minimize

noise levels at discrete frequencies.

Sipes are valleys cut across the tire,

usually perpendicular to the grooves,

which allow the water from the

grooves to escape to the sides in an

effort to prevent hydroplaning.

Treads are often designed to meet

specific product marketing positions.

High performance tires have small

void rations to provide more rubber

in contact with the road for higher

traction, but may be compounded

with softer rubber that provides

better traction, but wears quickly.

Mud and snow (M&S) tires are

designed with higher void ratios

to channel away rain and mud,

while providing better gripping

performance. Specialized tires will

always work better than general/

all purpose/all weather tires when

being used in the conditions the

specialized tires are designed for.

Tread Lugs and Voids

Tread lugs provide the contact surface

necessary to provide traction. As

the tread lug enters the road contact

area, or footprint, it is compressed.

As it rotates through the footprint

it is deformed circumferentially.

As it exits the footprint, it recovers

to its original shape. During the

deformation and recovery cycle

the tire exerts variable forces

into the vehicle. These forces are

described as Force Variation.

Tread voids provide space for the

lug to flex and deform as it enters and

exits the footprint. Voids also provide

channels for rainwater, mud, and

snow to be channeled away from the

footprint. The void ratio is the void

area of the tire divided by the entire

tread area. Low void areas have high

contact area and therefore higher

traction on clean, dry pavement.

Rain groove

The rain groove is a design element

of the tread pattern specifically

arranged to channel water away

from the footprint. Rain grooves are

circumferential in most truck tyres.

Many high performance passenger

tires feature rain grooves that are

angled from the center toward

the sides of the tyre. Some tire

manufacturers claim that their

tread pattern is designed to actively

pump water out from under the

tyre by the action of the tread

flexing. This results in a smoother

ride in different types of weather.

Sipe

Tread lugs often feature small

narrow voids, or sipes, that improve

the flexibility of the lug to deform as

it traverses the footprint area. This

reduces shear stress in the lug and

reduces heat build up. Testing of

identical siped and unsiped tires

showed measurable improvements

in snow traction and ice braking

performance, however diminishing

and extending braking distances

on wet and dry pavement by

a few feet on siped tyres.

Wear Bar

Wear bars (or wear indicators) are

raised features located at the bottom

of the tread grooves that indicate

the tire has reached its wear limit.

When the tread lugs are worn to

the point that the wear bars connect

across the lugs, the tires are fully

worn and should be taken out of

service. Most wear bars indicate

a remaining tread depth of 1.6

millimetres (0.063 in) and are

deemed "worn out" at that point.

Bead

The bead is that part of the tire

that contacts the rim on the wheel.

The bead is typically reinforced

with steel wire and compounded

of high strength, low flexibility

rubber. The bead seats tightly

against the two rims on the wheel

to ensure that a tubeless tire holds

air without leakage. The bead fit

is tight to ensure the tire does not

shift circumferentially as the wheel

rotates. The width of the rim in

relationship to the tire is a factor

in the handling characteristics

of an automobile, because the