- 6 -

Planetary gearboxes RG

Gearbox selection

Gearbox selection is made according to the following formulas for Continuous or Intermittent operation.

S1 - Continuous operation

for

S

p

> 60% or S

t

> 20 min

where:

T

2 nom

[Nm]

= Gearbox nominal torque

T

1 nom

[Nm]

= Motor nominal torque

T

2 ISO

[Nm]

= Gearbox nominal torque according to ISO

n

2 nom

[rpm]

= Output nominal speed

n

2 eqv

[rpm]

= Output average speed

S5 - Intermittent operation

for

S

p

< 60% or S

t

< 20 min

where:

T

2 acc

[Nm] = Gearbox max. acceleration

torque

T

1 acc

[Nm] = Motor max. acceleration

torque

i

[...]

= Reduction ratio

f

s

[...]

= Shock factor (see graph)

[...]

= Gearbox efficiency

Z

h

[1/h] = Cycle number per hour

T

2eqv

[Nm] = Equivalent torque, resultant by

individual torques of duty cycle

T

2max

[Nm] = Max. torque

n

2eqv

[rpm] = Cycle equivalent speed

n

2n

[rpm] = Cycle speed

n

2mid

[Nm] = Average speed

t

n

[ s ]

= Cycle times

t

1

...t

4

[ s ] = Acceleration, operation, deceleration, pause times

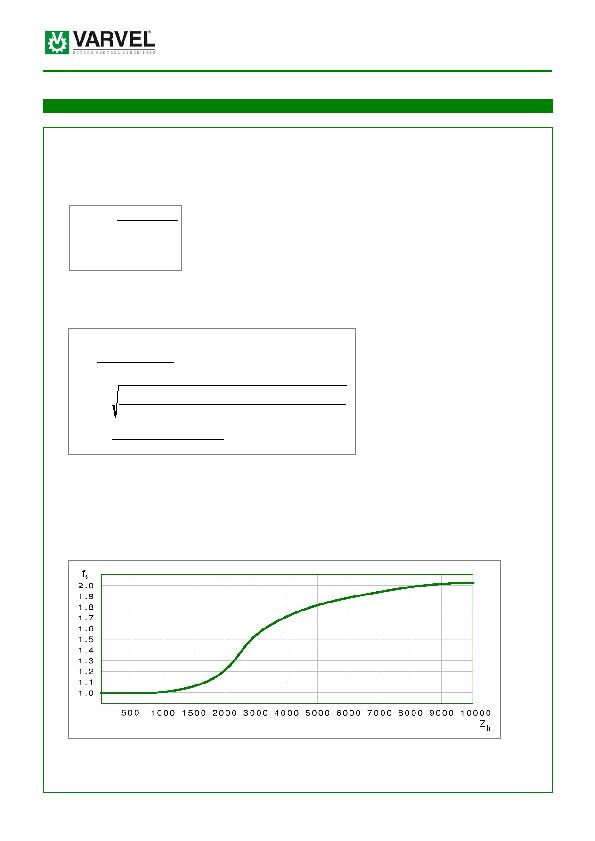

Shock factor

Shock factor is a service factor that keeps into account rapid motion inversions associated with quick acceleration times.

Such overloads must be considered when sizing.

f

s

-

Shock factor

Z

h

-

Cycle numbers per hour

Gearbox selection

t

t

t

n

t

n

n

n

t

n

t

t

n

T

t

n

T

T

t

t

t

t

3600

Z

f

i

T

T

n

1

n

1

n

2

1

1

2

eqv

2

3

midn

2

n

1

mid

2

1

n

1

midn

2

3

n

max

2

1

1

mid

2

3

1

max

2

eqv

2

4

3

2

1

h

s

acc

1

acc

2

nom

2

eqv

2

ISO

2

nom

2

nom

1

nom

2

n

n

T

T

65

.

0

i

T

T