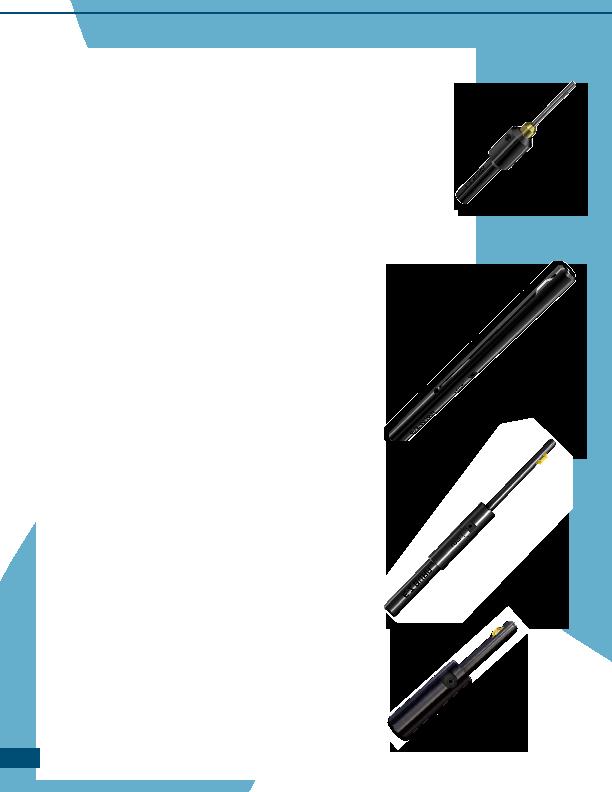

can deburr with the E-Z Burr Micro Series, the world's smallest solid arbor style

deburring tool. Economically priced, the E-Z Burr Micro Tool lets you deburr

thousands of super-small holes before the cartridge needs replacing. Still more

economy is provided by the two-piece construction, which lets you remove and

replace the cartridge in seconds while the tool is still in the spindle. That also

eliminates the need to handle and perhaps lose miniature parts.

and rear burr removal. They're the only deburring tools of their type that offer a

flexible blade which operates independently of springs and plungers. The result

is a solid shank not hollow like the competition and a more durable tool.

Additionally, the patented E-Z Burr Tool lets you change chamfer settings and

cutting blades without removal from the holder! And once you set the

desired chamfer it won't change even from blade to blade. These features

ensure less downtime, more production and higher profits.

feeds at least three times faster than regular HSS deburring tools. And the stan-

dard titanium nitrate-coated carbide insert lasts more than five times as long

as HSS blades. The inserts are adjustable, replaceable and can be changed

while the tool is in the machine. The E-Z Burr Carbide Series is ideal for

large production runs, heavy burrs and tough materials.

ing, these shorter length tools are made for limited space availability

with maximum flexibility and productivity in mind. The stubby series

comes in both high speed steel and carbide and manufacturers

can eliminate costly secondary operations by finishing parts

completely in one set up.