23

E-Z Burr has a unique spring-type high speed steel blade has set the standard for durability and reliability

in the tooling industry. These precision blades assure part-to-part consistency.

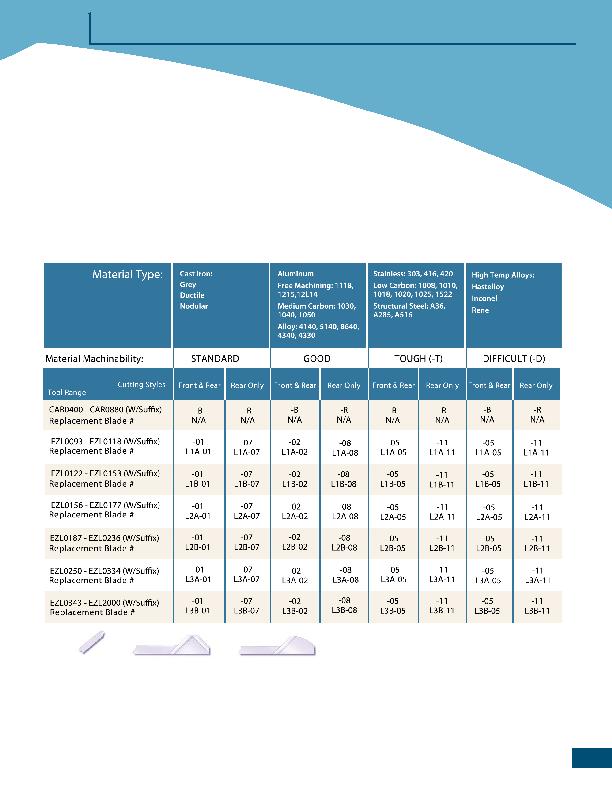

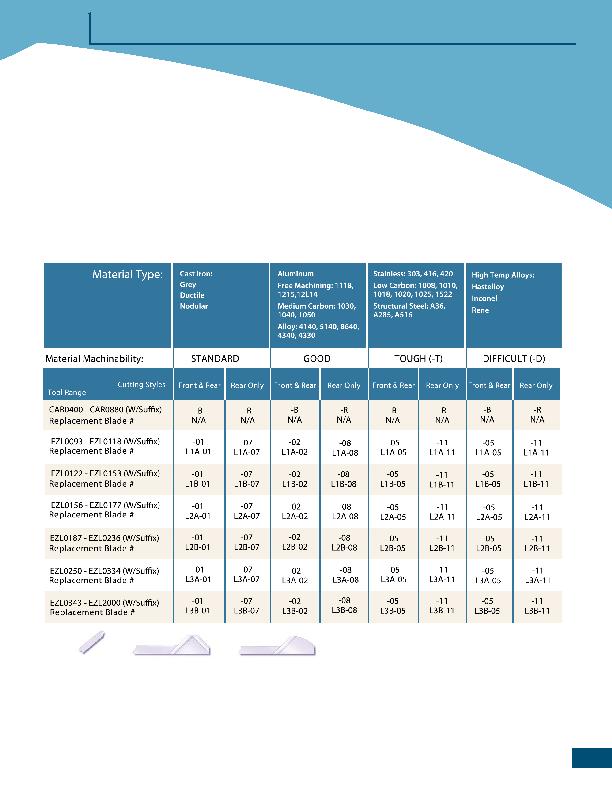

To determine the best HSS blade for your application, use this chart. You will need to know the following:

1. Determine your tool range (for assistance with this go to ezburr.com and click on E-Z Tool Calculator)

2. Determine the material group you are cutting

High Speed Steel Cutting Blades

Note: Special blade cutting angles by quotation only. Standard blade cutting angle

is 45°. We can produce any blade angle required, from 30° to 70°. Please specify

F (Front) and R (Rear) blade angle for angles other than 45°.

Cutting Features

Standard (10° Relief Angle)

Recommend for: Cast Iron, Zinc, Alloy Steel, Malleable Iron, High Carbon

Positive Rake (10° Relief Angle, 12° Positive Rake Angle)

Recommended for: Stainless, Aluminum, Low Carbon Steel

Negative Rake (10° Relief Angle, 8° Negative Rake Angle)

Recommended for:

Brass, Bronze

L1A

L1B

L2A

L2B

L3A

L3B

.093 - .118

.122 - .153

.156 - .177

.187 - .236

.250 - .334

.343 - 2.0+

B F R

B F R

B F R

B F R

B F R

B F R

Blade Series

For Sizes

Blade Styles

Blade Features

S (Standard)

P (Positive)

N (Negative)

Blade Series Example

L3A B 45 45 P

blade series

style

front angle

rear angle

feature

For help with ordering or technical assistance, contact your

local distributor or call E-Z Burr Tool Company at 800-783-2877.

B Style

R Style

REAR ANGLE

R e c o m m e n d a t i o n s f o r H S S B l a d e s

www.ezburr.com

1.800.783.2877

41180 Joy Rd, Plymouth, MI 48170

Easy. Fast. Built to Last.

B Style

R Style

B Style

R Style

RELIEF ANGLE

FRONT ANGLE

REAR ANGLE