Environment

Our environmental management

performance throughout the year was

good; however there was a slight increase

in the total environmental incident

frequency rate compared to 2011/12.

This can be attributed to an increase in

environmental incidents recorded on our

larger pipeline projects, specifically in the

management and control of storm water,

erosion and sediment during periods of

significant rainfall. Considerable focus

has been applied to improve these areas,

with good progress already being made.

A positive sign of this was the company

receiving the inaugural Australian Pipeline

Industry Association Environment Award

for our erosion and sediment control

practices on the QCLNG pipeline projects.

We continued to grow our capabilities

in environmental performance with a

focus on bringing in new managerial

skills and experience, and the continued

development of our workforce through

training.

To support the Seven Pillars, a range of

initiatives were implemented or continued

throughout the year, including:

· Safety leadership education program

for managers and supervisors

· Visiting leadership project safety visit

reports for off-site management, 172

reported for the year

· STOP THINK ASSESS campaign to

assist workers to recognise when

changes affecting safety occur

· Use of START cards and `See Say

Do' books for individual hazard

identification and reporting

· Personal safety plans for all staff

· Increased emphasis on high

consequence activities in risk

management and internal auditing

· Increased emphasis on accountability

for safety and the use of a just culture

model

· Trend analysis on incidents and

campaigns launched around critical

risk areas

· Early engagement with clients, joint

venture partners on safety standards

and systems

· Greater sub-contractor engagement

in safety in our procurement systems

· Increased awareness of the hierarchy

of control in managing high risk work

Type

Award

Project

Winner

Australian Biosecurity Award

APLNG

Winner

Inaugural APIA

Environmental Award

APLNG, QCLNG Export Pipeline,

QCLNG Narrows Crossing and GLNG

Certificate of Merit

Major Category for

Environmental Management

Upgrading Underground Link between

Orchard MRT and Tangs Plaza

Certificate of Merit

Major Category for

Environmental Management

C916 Beauty World Station

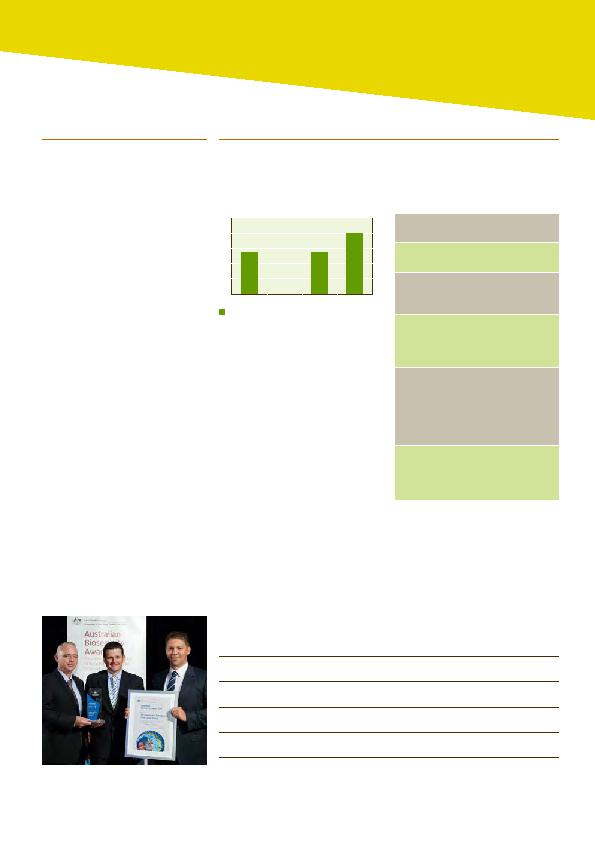

0.25

0.20

0.15

0.10

0.05

0.00

2009/10

2010/11

2011/12

2012/13

Serious environmental incident frequency rate.

All frequency rates calculated to a base

of 1,000,000 hours worked.

Australian Biosecurity Award

Six Pillars of Environmental

Management

During the year the company adopted

Six Pillars of Environmental Management.

The pillars are:

1. Emissions reduce emissions

resulting from our operations

2. Energy minimise energy use

throughout all operations

3. Water minimise water use and

effectively manage the quality

of water used and released

4. Waste minimise waste through

adoption of the waste hierarchy

and emphasis on the principles

of prevention, reuse and recycling

5. Materials optimise material usage

through the implementation of

green procurement strategies that

increase the efficiency of resource

use and produce an environmentally

beneficial outcome

6. Biodiversity avoid, minimise

and mitigate negative impacts

on biodiversity while optimising

positive impacts

Similar to the Seven Pillars of Safety,

they will provide the framework for all

environmental management activities

across the McConnell Dowell Group.

Recent Awards

7