to say?

you want to feature a story in our

email us now at info@acrassoc.com.au

National Concrete Solutions (NCS) were approached for a solution to the deteriorating floor joint edges in a

very large store in regional NSW.

Stacking and movement of the large reels of product, is undertaken by AGV

(automatic guided vehicles) with point loading on the hard wheels of around

5MT. This concentrated loading combined with rotation and turning loads

was breaking the joint edges and ultimately causing stoppages, risk to the

equipment and potential safety hazards to personnel.

Due to the plant operating continuously the

designed solution needed to provide a fast turn

around and rapid return to service.

"NCS were engaged to carry out trial jo

int repairs using high strength epoxy grout

and to map the joint condition throughout the reel store" Commented David

Neveling "Site Project Engineer".

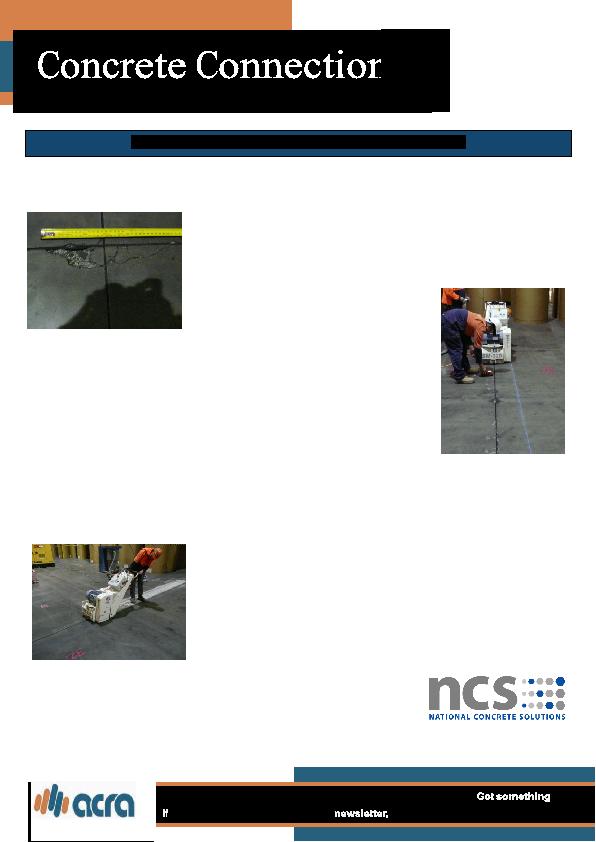

The custom solution developed by NCS incorporated the excavation of concrete

either side of the joint to a specific profile, followed by reinstatement with high

strength epoxy.

The smooth finished concrete floor had post cut joints at approx. 6 meter spacing.

Specialist machinery and operators were engaged to excavate the specific repair profile prior to reinstatement

with high strength epoxy grout.

Finally the joint was recut and sealed with a semi ridged epoxy sealant to provide added support to the joint

edges.

The result was a smooth surface for transition by the AGV's with superior

resistance to edge spalling due to the high strength epoxy grout and high

edge support characteristics of the semi rigid joint sealant.

David commented "The repairs are performing well and showing no signs of

distress under constant AGV traffic"

The high early strength of the products used also assisted in fast turn

around and return to service.

Media Enquires:

Brett Jones

State Manager - NSW

0409 152 428