30

GA

/ Vol. 5 / No.9 / SEPTEMBER 2013

By Kestutis Volungevicius

Head of FL Technics

Industry News

CFM56 Family

success triggers

the demand

for training in

Eastern Europe

and the CIS

During the Jubilee Paris air show

Boeing and Ryanair finalised an

order for 175 Boeing 737-800

airplanes powered by CFM56-

7B engines worth $3.7 billion.

Meanwhile, last year the Russian

national carrier - Aeroflot also

announced the plans to introduce

around 50 Boeing 737 NG to

its fleet. These figures indicate

a steadily growing demand for

the CFM56 family engines as

airlines around the world are

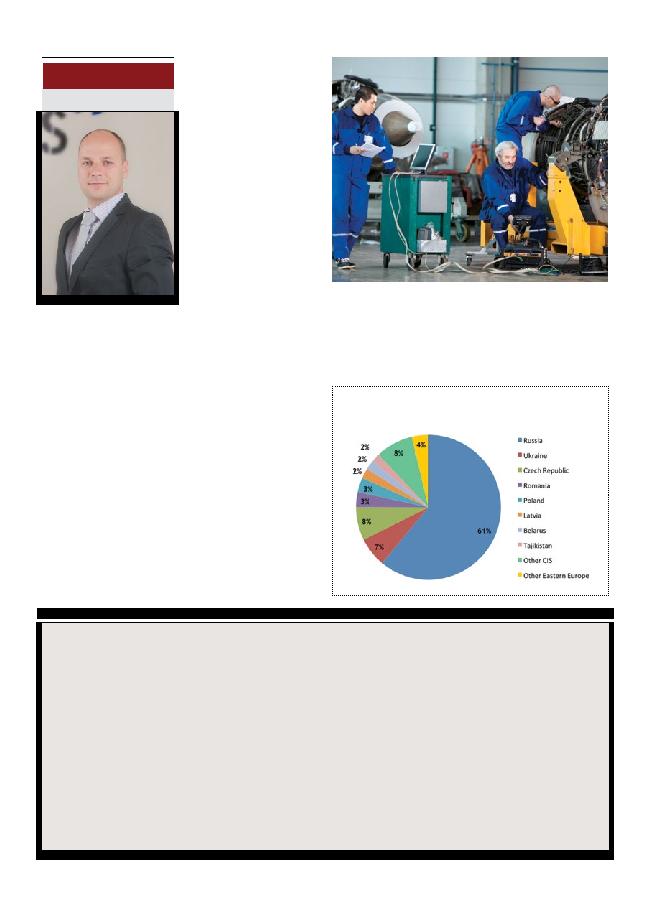

Table 1. CFM56 Family engine fleet distribution in

Eastern Europe, the Baltics and the CIS

renewing their fleets thus

building the need for relevant

engine specialists, particularly

in Eastern Europe and the CIS.

CFM56 family remains one

of the most popular engine types

both globally and regionally.

For instance, approx.1240

CFM56 engines are being

operated in Eastern Europe,

Russia and the CIS. Moreover,

these engines correspond to

about 94-95% of the entire

narrowbody aircraft fleet in the

Baltics and the CIS. The figures

clearly indicate that in the

near future the CFM56 engine

market in the region should

show no signs of shrinking.

While the regional engine

market is being dominated by

the CFM engine family, local

demand for a particular engine

version within the family is

changing. It is estimated that

in the nearest future Russian

carriers alone will acquire

about 1700 new narrow-body

aircraft. Being in their second

fleet renewal round already,

Russian airlines are not only

further phasing out their Soviet-

era machines, but also shifting

towards newer generation

aircraft, like Boeing 737 NG. It

indicates that while the demand

for CFM56-3 series maintenance

services remains high, in a few

years time the market might

slowly start shrinking, giving

place to newer CFM56-7 series

for B737 NGs. Moreover, we

are highly likely to observe a

faster development process with

regard to CFM56-5B engines,

powering Airbus A320s.

`Aiming to support

manufacturers and their new

generation aircraft, CFM has

designed a number of even more

sophisticated solutions for better

engine performance. Newer engines

help to lower maintenance costs by

up to 4%. Meanwhile, the regional

demand for relevant specialists and

their training will remain quite high,

as many local operators and MROs

are further investing in both inventory

and technical personnel, required

to support day-to-day operation of

the renewed fleet. We anticipate that

in the upcoming several years the

demand will grow not only for the

CFM56 Engine Training, but also

for the more advanced programs,

first and foremost those which

focus on the NDT inspections. ·

Industria de Turbo Propulsores, S.A.

(ITP), and Rolls-Royce Plc have signed

an agreement by which ITP will be

responsible for the supply of Low Pressure

Turbines (LPT) for two new engines:

the Trent XWB-97 for the Airbus

A350-1000 and the Trent 1000-TEN for

all versions of the Boeing 787. This

contract will generate sales for ITP of 4

million euros in the next 30 years.

Ignacio Mataix, Chief Executive Officer of

ITP said " These contracts are a very important

step in the ITP strategic plan which includes

doubling ITPīs sales in the 2011-2015 period, as

well as continuing to provide Rolls-Royce with

Low Pressure Turbines for engines powering

twin aisle commercial aircraft. For ITP this

confirms a continuation in the growth path, as

well as continuation of investments in leading

programmes with high technological content."

In both agreements ITP will participate

as a Risk and Revenue Sharing Partner for

the life of the programs, hence extending

ITPīs participation to the complete family of

Rolls-Royce engines for twin aisle commercial

aircraft. Once the new aircraft enter service ITP

estimates to have a 50% share in the worldwide

market of LPTs for twin aisle aircraft.

ITP will be responsible for the Design,

Manufacture and Assembly of the Low

Pressure Turbine module for both engines.

The Low Pressure Turbine Module is one

of the main engine modules in modern large

turbofans. ITP will perform the complete

design of the turbines, including all phases

of the design, from conceptual design, to

detail design and development utilizing

the latest technology In order to produce

the cleanest and most efficient turbines.

ITP will manufacture all the key

components of the turbines in the facilities

of the ITP Group utilizing the latest

manufacturing technologies and will perform

the module assembly in order to supply a

complete assembled module to Rolls- Royce,

ready to be installed in the engines.

These new programs will generate

additional growth in ITP and will require

investments in excess of 250 million euro

in Research and Development, as well as in

industrial facilities to produce the turbines. ·

TRENT ACTION