Series Wound 2 Lead

Series Wound 4 Lead Reversing

Series Wound 3 Lead Reversing (Split-Series)

D.C. Shunt Wound

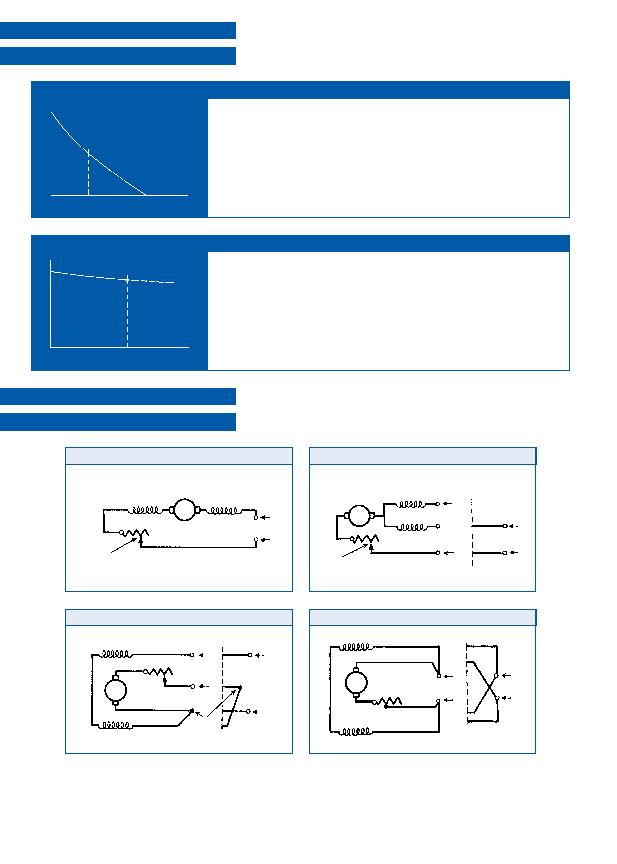

Shown is a typical "torque/speed" characteristic for series wound motors. Series wound motors can be

wound for A.C. or D.C. supply. A.C. wound units when operated from a similar D.C. voltage will have

approximately 15% increase in output.

Suitable for reversing as standard i.e. 4 leads brought out (two armature and two field). Series motors can

be supplied as 3 lead reversing (split field) (the motor runs on one field coil at a time with approximately

30% power loss), change of direction being affected by a single pole switch.

As will be seen from the characteristic the speed varies inversely with the load, consequently series wound

motors should not be oversized for their particular application as this will result in the motor running at much

higher speeds than required.

It is possible to control the speed of this type of motor by means of a variable resistance transformer in a

ratio 5:1 although this can vary depending on the application.

ARMATURE

ARMA

TURE

Field

Field

Field

Field

White

White

White

Red

Red

White

If speed control required

insert rheostat thus

Join

and

insulate

Reverse

rotation

If speed control required

insert rheostat thus

Supply

Supply

ARMATURE

ARMA

TURE

Field

Field

Field

Field

White

White

Red

Red

Red

White

White

Reverse

rotation

Reverse

rotation

If speed control required

insert rheostat thus

Supply

Supply

Supply

Supply

Characteristics of Commutator

Motors

Connection Diagrams for Wound

Field Commutator Motors

Series Wound Motors

FULL LOAD

SPEED

TORQUE

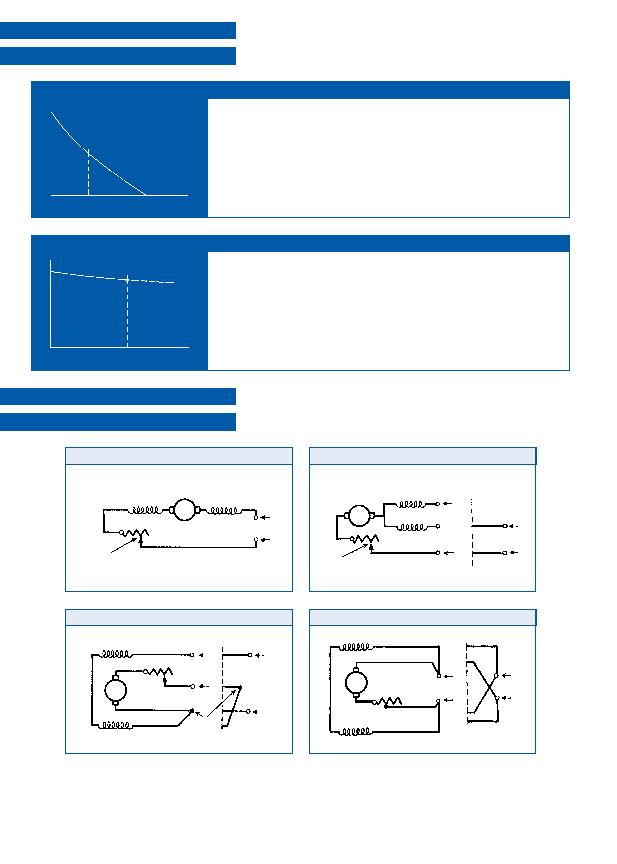

Shown is a typical "torque/speed" characteristic for D.C. shunt wound motors. This type of unit has constant

speed characteristics, the difference between no load and full load speed being between 10% and 20% of

rated speed.

Suitable for reversing as standard i.e. 4 leads brought out (two armature and two fields). The speed can be

controlled by means of a variable resistance in series with the armature by a ratio of approximately 6:1,

however this can vary considerably depending on the application. Alternatively if an A.C. supply is

available a speed range of up to 25:1 can be obtained by means of a D.C. thyristor controller.

IMPORTANT: It must be noted, in mind when reducing the motor speed the armature cooling fan efficiency

drops and therefore it is wise to reduce the rating or load of the motor by 3040% over a speed range of

10:1 and by 50% for a speed range of 25:1.

Shunt Wound Motors

SPEED

FULL LOAD

TORQUE

14

11

13

12

If speed control required

insert rheostat thus

44