Some of your questions

answered!

Which motors/gearmotors are electrically

reversible?

All motors and gearmotors shown in this catalogue are reversible.

(except shaded pole). Some require a full stop before reversing.

Can continuous duty motors/gearmotors be used

intermittently?

All rated torques shown in this catalogue are for continuous

operation. Continuous duty products can be used intermittently.

Operation at loads higher than nameplate ratings is possible for short

periods as long as there are rest periods for cooling. Loads must not

exceed the mechanical rating for the gears (see page 5) without

consulting our sales engineers. The temperature of the motor should

be monitored during testing to make sure it is not overheating.

Can single speed motors and gearmotors ever be

operated as variable speed?

Three phase and some Permanent Split Capacitor designs may be

operated as variable speed with a frequency inverter. Commutator

motors can be operated as variable speed using a thyristor controller.

Is an adjustable speed system ever appropriate

for a single speed application?

Adjustable speed systems are sometimes appropriate for single

speed applications. If the desired speed is not known or not offered in

a single speed product, an adjustable speed system may be set to

the desired speed.

What is IP 54?

The IP number is an international system for rating enclosures.

An IP 54 is for protection against dust and splashing liquids.

What is meant by the term self locking?

Self locking refers to the tendency of some gearing to resist

movement when the gearmotor is at rest and the load is attempting to

move. An example is a load on a conveyer belt trying to drive the

system backwards.

Which gearheads are self locking?

Parallel shaft gearheads and right angle gearheads with low ratios

are generally not considered to be "Self locking". Right angle

gearheads with ratios greater than 25:1 are often considered to be

"Self locking". They will resist movement up to their torque rating. As

the gearing nears the end of its useful life or if it is subjected to

overload conditions, it may wear to the point where it is no longer

"Self locking". Self locking gearing is not a recommended method for

preventing movement in applications where this movement may

cause injury or damage. An external brake is recommended for those

applications. (see pages 6, 45 and 72)

A

Q

A

Q

A

Q

A

Q

A

Q

A

Q

A

Q

Can more than one motor be operated from a

single control?

Operation of more than one motor from a single control is not

normally recommended. However, when cost is a primary concern, a

multiple motor/single control system with either permanent magnet

motors and control, or 3 phase motors and control may be

successfully implemented. More than one permanent magnet motor

may be operated with a single permanent magnet control as long as

the sum of the motor currents does not exceed the rated output

current of the controller. Comprehensive testing is recommended

because this type of system may produce fluctuation or drifting speed

output. More than one 3 phase motor may be operated with a single

3 phase control. Motor speeds should not fluctuate as long as the

motors are not overloaded and the sum of the motor currents does

not exceed the rated output current of the control.

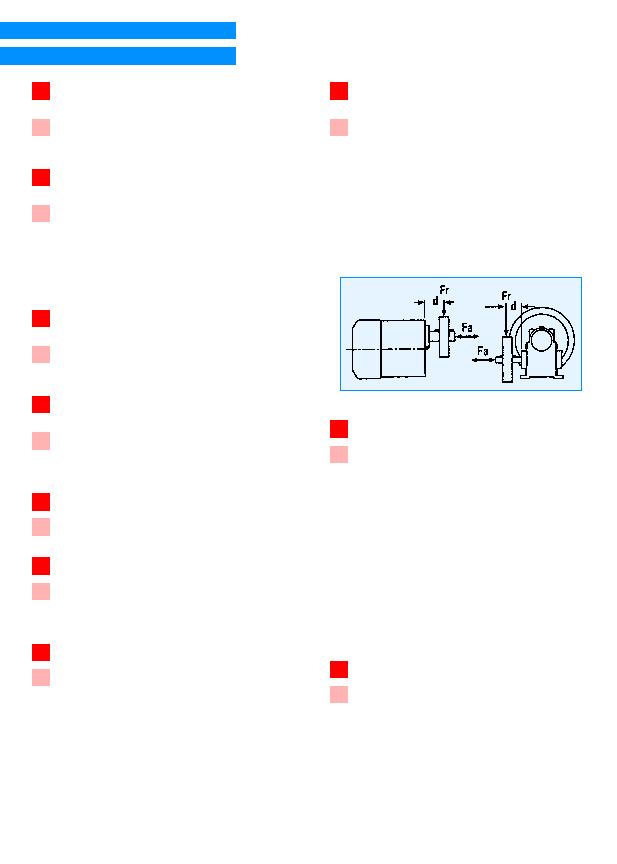

What is radial load?

Radial load is a force pushing or pulling the side of the output shaft. It

is shown as Fr above. Exceeding the allowable radial load for a

motor or gearmotor will cause premature wear of output shaft

bearings and gearing and could cause the shaft to break.

Fr may be the result of a weight on the shaft, belt tension or torque

transmitted through a belt, chain, gear, or certain flexible couplings. A

permissible radial load, Fr, is shown for each motor and gearmotor. In

calculating these values, the following assumptions were made:

1) The radial load is in the worst case direction, i.e. pushing or

pulling the shaft sideways.

2) The motor or gearmotor is delivering rated torque.

3) The radial load was applied at distance "d" from the hub or

mounting surface. Higher radial loads may be applied closer in on

the shaft. Lower radial loads are permitted further out on the

shaft.

Flexible couplings are often used to avoid radial load. Most flexible

couplings are designed so that they do not transmit radial load,

however this should be verified by the coupling manufacturer.

What is axial load?

Axial load is a force on the output shaft into or out of the motor or

gearmotor. It is shown as Fa in the diagram above. Exceeding the

allowable axial load for a motor or gearmotor will cause premature

wear of output shaft bearings and gearing.

A

Q

A

Q

A

Q

Radial and Axial load parameters

4