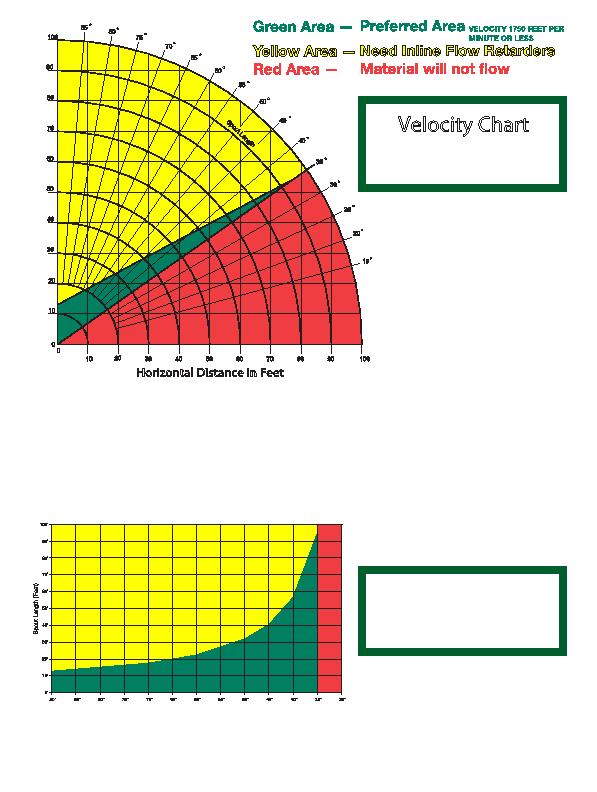

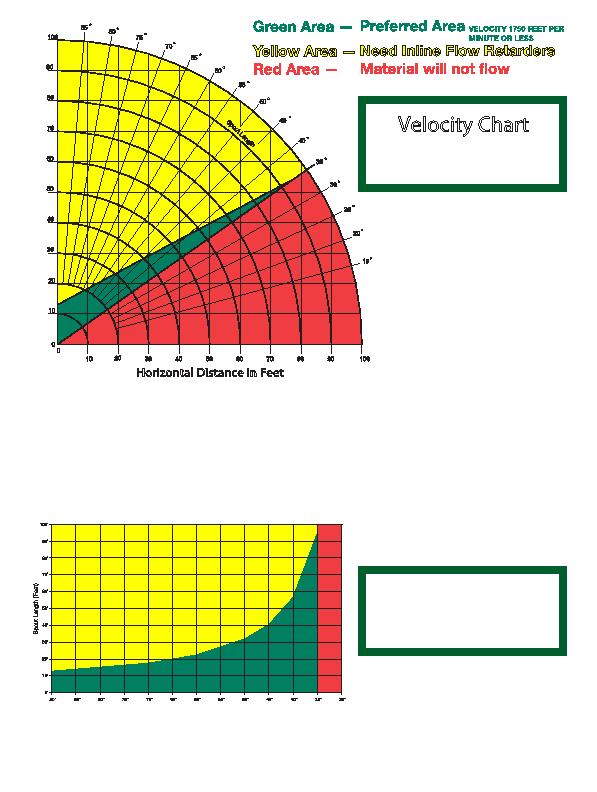

Spo

ut L

eng

th

100

90

80

70

60

50

40

30

20

10

0

0

20

30

40

50

60

70

100

90

80

10

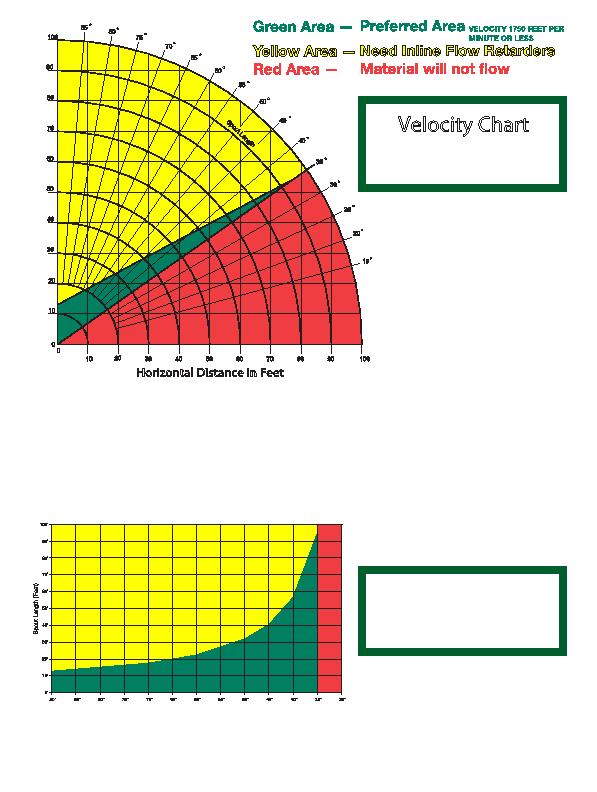

85

80

75

70

65

60

55

50

45

40

35

30

25

20

15

V

ertical Distance in Feet

Horizontal Distance in Feet

Velocity Chart

To be used in layout and selection

of velocity reduction equipment.

This chart is a guideline for spouting corn, soybeans or wheat in round steel spouting. You should run spouts

in the green area. The yellow area requires ow retarders. The red area is too at to ow.

Velocity can be reduced by lowering angle of spout. In 90° spouts, a ow retarder is recommended every

12 feet. In 60° spouts, a ow retarder is recommended every 25 feet. In 45° spouts, a ow retarder is

recommended every 40 feet. In 35° spouts, a ow retarder is recommended every 95 feet.

PREFERRED SPOUTING RUNS. By dropping vertical and installing vertical ow retarders and vertical drop

turnout, you can often eliminate inline ow retarders. The reduction of velocity protects and helps maintain

quality of product being handled and reduces wear on spouting and accessories.

Green area represents

spout that does not require

Inline Flow Retarders.

***Urethane lined spouting requires 38 degrees or greater. UHMW lined spouting will increase velocity. Wet corn or ground feed ingredients will not ow

at 35 degrees. Feed pellets have varying ow rates. Flow retarders help maintain quality of feed pellets. Chart information is for guidelines only -- actual

results will vary.