-

53

-

Gearboxes Series RS & RT

When back-driving a worm gear set using the worm wheel as input, the efficiency is lower than forward-

driving and, by varying the design data, back-drive efficiency can be reduced to zero obtaining a self-lock-

ing, or irreversible, gear set.

When back-driving the worm gear, internal friction tends to lock the mesh, and the bigger the applied torque

is, the more mesh friction increases proportionally augmenting the lockage at the same time.

The most obvious example is during braking or slowing-down where the inertial load will try to back-drive

the worm shaft.

A worm gear is intended as a self-locking unit when the lead angle is less than the friction angle (arc tan-

gent of friction coefficient).

Tooth contact is dynamic even when the mesh velocity is zero, as vibrations in a non-rotating gear set can

induce motion in the tooth contact.

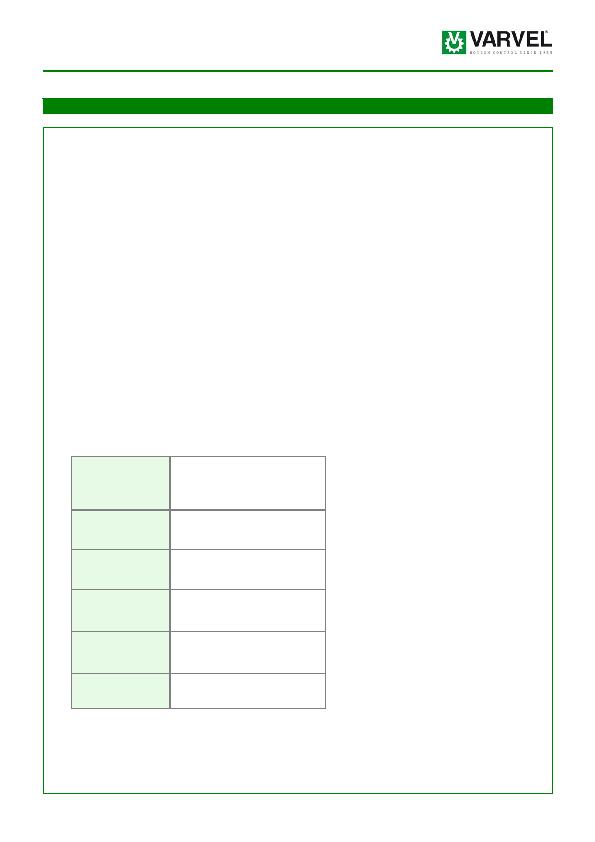

To provide a safety factor, a 3° lead angle is recommended for full self-locking condi-tion, and 10° lead an-

gle for poor self-lock-ing condition, according to the table of relations between lead angles and self-locking.

Lead angle

Static

self-locking

10°

20°

High back-driving

5°

10°

Good back-driving

Poor self-locking

3°

5°

Poor back-driving

Good self-locking

1°

3°

Full self-locking

20°

Full back-driving

Back-Driving and Self-Locking