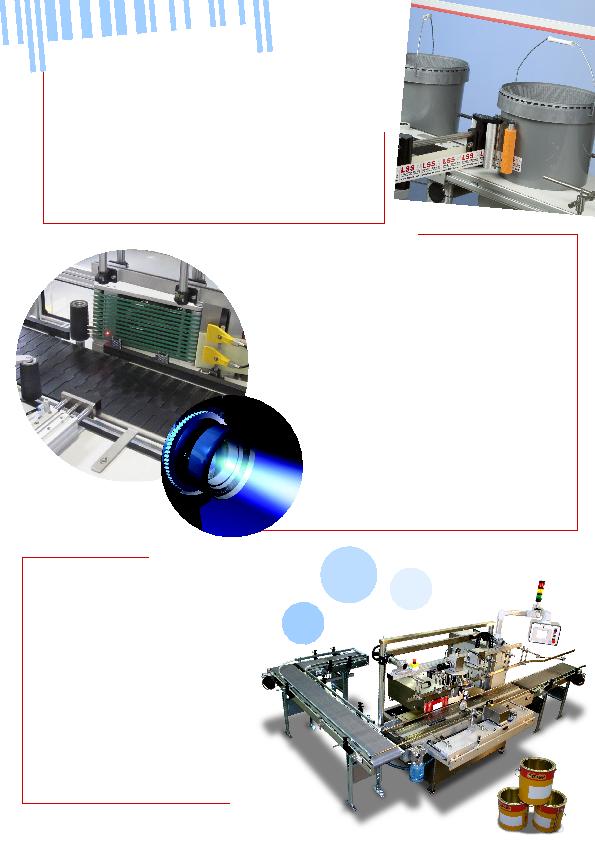

High speed labelling HCL

Faster filling machines sometimes call for faster labelling

machines. For the purpose of applying one or several smal-

ler labels onto containers, LSS has developed a machine that

can rotate and orientate without stopping the product. The

products are typically larger conical or cylindrical 2.5 to 20

liter products. The products will be orientated in relation to

the handle and rotated between belts during transportation

in order to have the labels placed at the right position. This

principle of labelling has a capacity of up to 45 pcs. of 12 liter

containers per minute, including lifting up the handle.

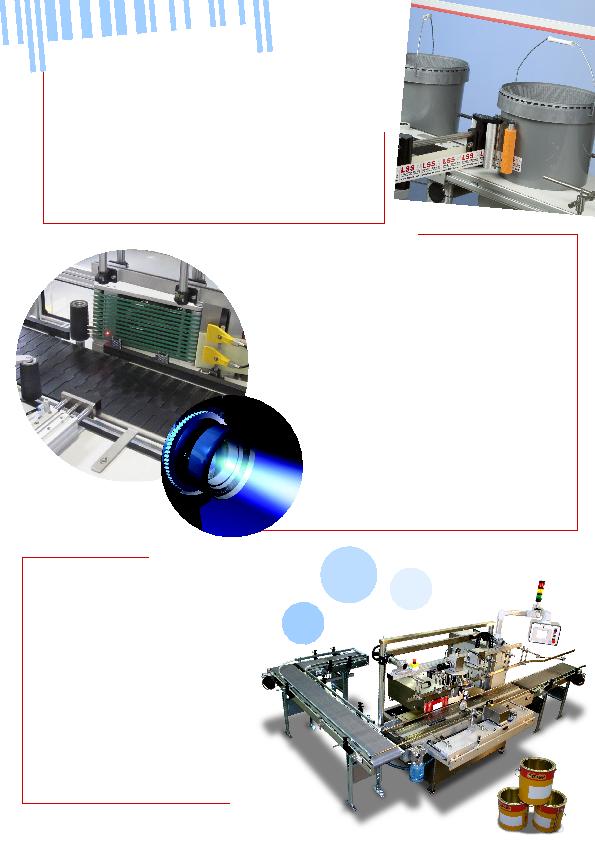

Combined machines

Example of combined machine made

of single sided MCL module for large

conical products and the CL 3 roller

indexer for smaller cylindrical full

wrap labelling.

The illustrated machine is an off-

line machine.

The layout is U-shaped, thus

allowing one person or machine to

load and unload the labelled cans

again.

CLM Clever thinking!

CLM, Can Labelling Multi-purpose. This "all-purpose" machine

allows you to label almost all kinds of different shapes and sizes

of products. Conical, cylindrical, small or large containers, with

or without handles, filled or empty.

The principle of this machine allows the dispenser and apply

unit to be adjusted in all directions. This makes it possible

to apply a full wrap label on cylindrical products and it will

also be able to apply front and back side labels onto conical

products with only one label dispenser. This also means

that both the front side and the back side label must

be on the same label web, which is a new and

clever way of thinking. One of the additional be-

nefits are that the machine can be fully operated

from one side only. Along with handle lifting

device and the possibility of printing barcodes

directly onto large labels, this machine gives

all possibilities with extremely low change over

times.